Top 10 Benefits of Using Actuated Butterfly Valves in Industrial Applications

In the realm of industrial applications, the choice of valves plays a critical role in ensuring efficient operation and control of fluid dynamics. Among the variety of options available, the actuated butterfly valve stands out as a highly beneficial solution for many industries. These valves, characterized by their quarter-turn operation and compact design, provide a unique combination of versatility, reliability, and cost-effectiveness. As industries increasingly demand more streamlined processes and robust flow control mechanisms, the adoption of actuated butterfly valves continues to gain momentum.

One of the most significant advantages of using actuated butterfly valves is their ability to provide quick and precise regulation of flow with minimal effort. Their electronic or pneumatic actuation allows for automation and integration with control systems, enabling real-time responsiveness to changes in process conditions. Furthermore, the lightweight structure of these valves reduces the overall burden on piping systems, minimizing installation costs and simplifying maintenance.

In this article, we will delve into the top ten benefits of incorporating actuated butterfly valves within various industrial settings. From enhanced operational efficiency to reduced energy consumption, understanding these advantages can aid industries in making informed decisions about their fluid management systems. As we explore each benefit, it will become evident that actuated butterfly valves are not just a practical choice, but a strategic investment for the future of industrial operations.

Overview of Actuated Butterfly Valves and Their Functionality

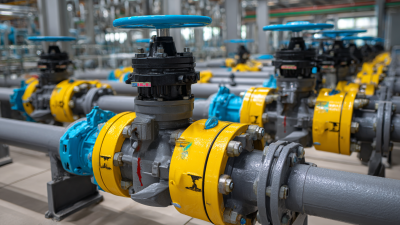

Actuated butterfly valves are essential components in various industrial applications, known for their ability to efficiently regulate the flow of liquids and gases. These valves consist of a rotating disc that pivots around a central axis, allowing for quick opening and closing with minimal pressure drop. The incorporation of an actuator enhances their functionality, enabling automated control that increases operational efficiency and safety in demanding environments.

When integrating actuated butterfly valves into a system, it’s important to consider the specific requirements of your application. For instance, selecting the right actuator type—electric, pneumatic, or hydraulic—can significantly impact performance. Additionally, ensure that the material of the valve disc and body matches the properties of the fluids being controlled to prevent corrosion and ensure longevity.

Tips: Regular maintenance is crucial for the longevity of actuated butterfly valves. Inspect seals and actuator functionality routinely to avoid unexpected failures. Implementing a monitoring system can also help detect issues early, ensuring optimal performance without costly downtime. Always adhere to manufacturer guidelines for installation and operation to maximize the benefits of these versatile valves.

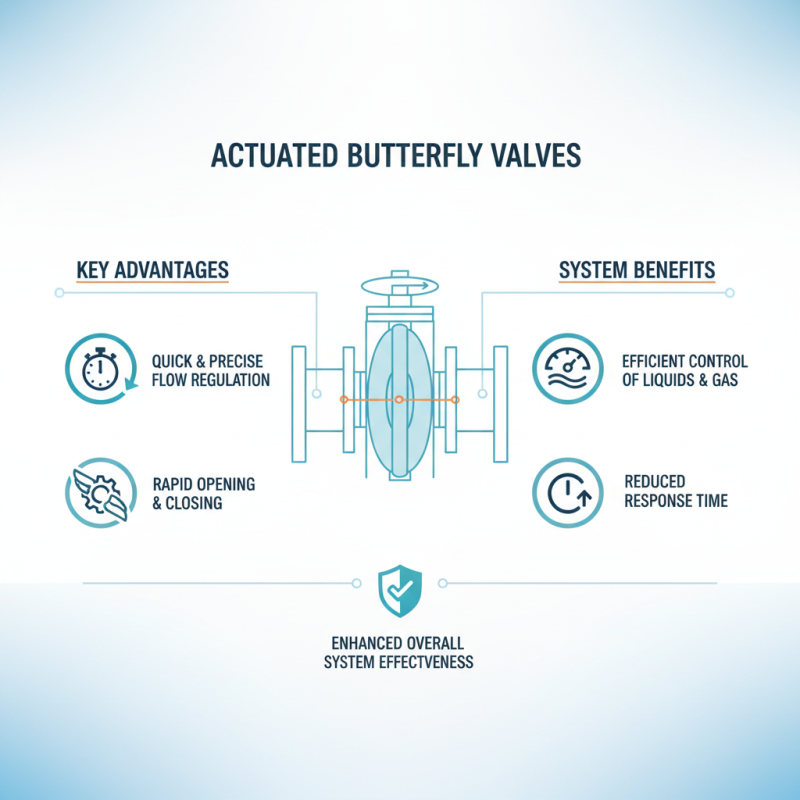

Key Advantages of Actuated Butterfly Valves in Fluid Control

Actuated butterfly valves are essential components in fluid control systems across various industrial applications. One of the key advantages of these valves is their ability to provide quick and precise flow regulation. The actuator mechanism enables rapid opening and closing of the valve, allowing for efficient control of liquids and gases. This efficiency not only helps in maintaining the desired flow rates but also reduces the response time in critical processes, enhancing overall system effectiveness.

Another significant benefit of actuated butterfly valves is their compact design and lightweight construction. Unlike traditional valve types, these valves occupy less space and can be easily installed in tight locations, making them ideal for modern industrial setups where space is a premium. Additionally, their simple construction minimizes maintenance requirements, leading to lower operational costs over time. The combination of reliability and ease of use makes actuated butterfly valves a preferred choice for industries such as water treatment, chemical processing, and HVAC systems, ensuring optimal control of fluid dynamics.

Energy Efficiency: How Actuated Butterfly Valves Save Power and Costs

Actuated butterfly valves are becoming increasingly popular in various industrial applications due to their significant energy efficiency benefits. These valves operate with minimal power requirements, utilizing a simple rotating mechanism that allows for quick opening and closing. This design not only reduces the energy consumption needed for valve operation but also minimizes the wear and tear on other system components. As a result, industries can experience decreased operational costs while enhancing overall system performance.

Moreover, actuated butterfly valves are highly effective in flow control, allowing for precise modulation of fluids within pipelines. By adjusting the valve position precisely, industries can optimize flow rates, reducing unnecessary energy wastage caused by over-pumping or backpressure. This dynamic control is especially vital for applications involving water treatment, HVAC systems, and chemical processing, where maintaining the right flow can lead to substantial energy savings. Embracing these valves leads to lower utility bills and fosters sustainable practices, making them a smart investment for modern industrial operations.

Durability and Maintenance: The Long-Term Benefits of Butterfly Valves

Actuated butterfly valves are increasingly favored in industrial applications due to their remarkable durability and low maintenance requirements. These valves are designed with a simple yet effective mechanism that minimizes wear and tear, ensuring a long lifespan even in demanding environments. The materials used in their construction, often resistant to corrosion and wear, contribute significantly to their ability to withstand harsh operating conditions. By investing in actuated butterfly valves, industries can minimize the frequency of replacements, leading to cost savings and reduced downtime.

Maintenance is another critical aspect where butterfly valves excel. Their straightforward design allows for easy access to internal components, facilitating quicker inspections and servicing. Unlike more complex valve types, which may require specialized tools or extensive disassembly, butterfly valves can often be maintained with basic equipment. This ease of maintenance not only reduces the labor costs associated with upkeep but also enhances operational efficiency. Thus, the long-term benefits of using actuated butterfly valves in industrial settings manifest not only in their durability but also in their ability to streamline maintenance processes, making them a practical choice for various applications.

Top 10 Benefits of Using Actuated Butterfly Valves in Industrial Applications

| Benefit | Description | Long-Term Value |

|---|---|---|

| Durability | Actuated butterfly valves are designed to withstand harsh conditions, ensuring longevity in industrial environments. | Reduced replacement costs over time. |

| Low Maintenance | These valves require less frequent maintenance compared to other valve types, saving time and labor. | Lower operational costs and minimal downtime. |

| Space Saving Design | Compact valve design allows for efficient use of space in industrial setups. | Increases layout flexibility in piping systems. |

| Quick Operation | Fast opening and closing cycles for effective flow control. | Improved system efficiency and responsiveness. |

| Versatility | Can be used in various applications including water, gas, and chemical processing. | Broadens the range of applications without needing multiple valve types. |

| Cost-Effectiveness | Lower initial investment combined with low maintenance makes them cost-effective. | Provides significant savings over the lifecycle of the valve. |

| Reduced Leakage | Designed to minimize leakage, enhancing safety and efficiency. | Provides reliability in critical applications, reducing risks. |

| High Flow Capacity | Allows large volumes of fluid to pass through, improving throughput. | Increases productivity in industrial processes. |

| Easy Integration | Can be easily integrated into existing systems with minimal modifications. | Saves installation time and costs. |

| Strong Performance | Consistent operation under varying temperature and pressure conditions. | Ensures operational stability in fluctuating environments. |

Applications in Various Industries: Use Cases for Actuated Butterfly Valves

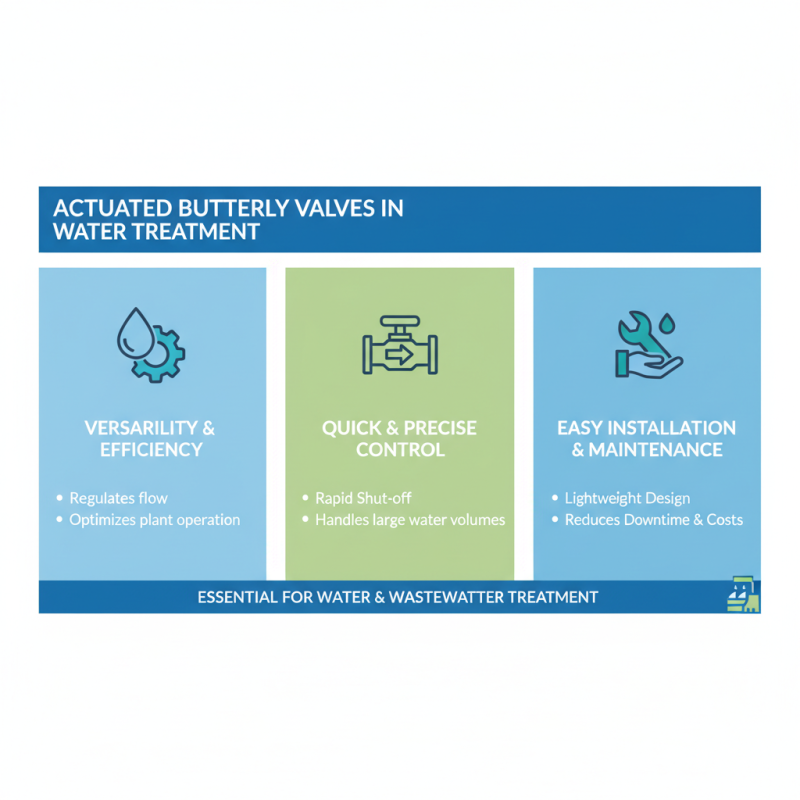

Actuated butterfly valves play a pivotal role across various industries due to their versatility and efficiency. In the water and wastewater treatment sector, these valves are essential for regulating flow and ensuring optimal operation within treatment plants. Their ability to provide quick shut-off and precise flow control makes them ideal for handling large volumes of water. Additionally, their lightweight design allows for easier installation and maintenance, reducing downtime and operational costs.

In the chemical processing industry, actuated butterfly valves are vital for managing the flow of corrosive and viscous fluids. Their compact design and ability to handle high-pressure applications contribute to enhanced safety and reliability in critical processes. Moreover, in the HVAC sector, these valves are commonly used to control airflow in ventilation systems. By precisely adjusting the valve position, energy consumption can be optimized, contributing to more sustainable building operations. Overall, the adaptability of actuated butterfly valves across these applications highlights their importance in enhancing efficiency and safety in industrial environments.

Related Posts

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

Emerging Trends in Butterfly Valves Industry Exhibited at China Import and Export Fair 2025

-

10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability

-

Exploring the Future of Actuated Valves: Innovations Shaping the Global Market Growth to $10 Billion by 2028