Top 10 Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

In the realm of industrial applications, the choice of valves can significantly influence operational efficiency and system reliability. One standout option is the triple offset butterfly valve, designed to excel in various demanding environments. This innovative valve type combines robust construction with advanced engineering, leading to enhanced performance and longevity. Unlike traditional valves, the triple offset butterfly valve features a unique design that minimizes friction, allowing for smooth operation and tight sealing, contributing to substantial energy savings and reduced maintenance costs.

As industries continue to evolve, the need for reliable and efficient flow control solutions becomes increasingly critical. The advantages of adopting triple offset butterfly valves extend beyond basic functionality. These valves offer superior durability, impressive pressure and temperature handling capabilities, and versatile applications, making them suitable for a range of sectors including oil and gas, water treatment, and chemical processing. Investing in these valves not only streamlines operations but also bolsters system integrity and safety. In the following sections, we will delve deeper into the top ten benefits that make triple offset butterfly valves an essential component in modern industrial infrastructure.

Benefits of Triple Offset Butterfly Valves in Flow Control Efficiency

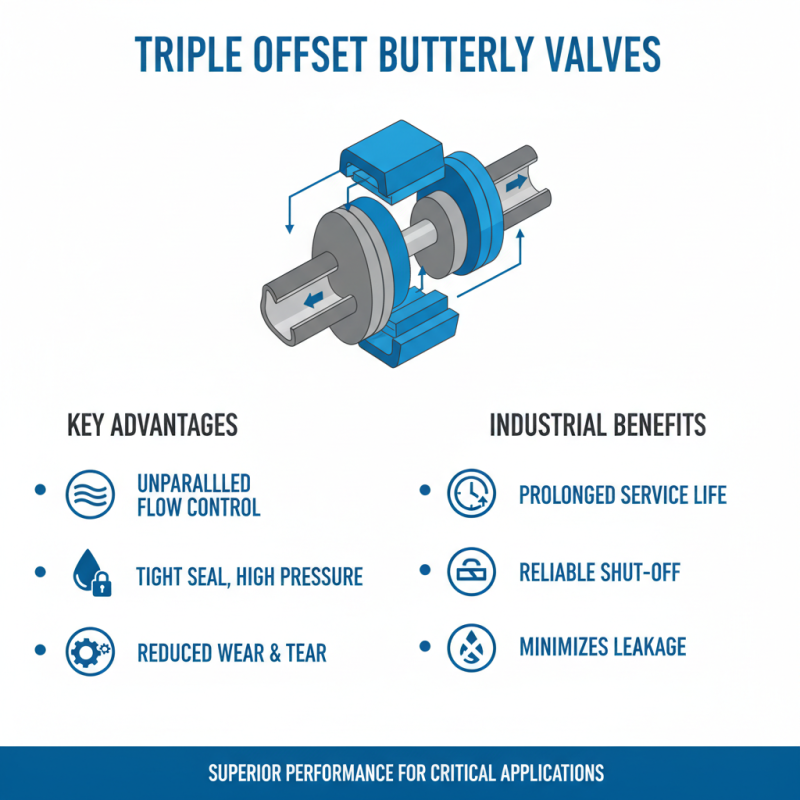

Triple offset butterfly valves are gaining recognition in industrial applications for their unparalleled flow control efficiency. One of the primary advantages of these valves is their unique design, which allows for a tight seal even under high-pressure conditions. The triple offset geometry eliminates friction between the valve seat and disc during operation, resulting in reduced wear and tear and prolonged service life. This feature is particularly beneficial in sectors requiring reliable shut-off capabilities, as it minimizes the risk of leakage and ensures consistent flow rates.

Moreover, triple offset butterfly valves provide exceptional flow characteristics. The streamlined shape of the disc allows for low resistance, promoting better flow rates compared to traditional valve types. This efficiency translates to lower energy consumption in pumping systems, making them an eco-friendly option for industries looking to reduce operational costs. Additionally, their lightweight construction facilitates easier installation and maintenance, further enhancing their suitability for diverse industrial environments. By adopting triple offset butterfly valves, facilities can achieve improved process control and greater reliability in fluid handling, making them an ideal choice for modern industrial applications.

Enhanced Seal Integrity: How Triple Offset Design Reduces Leakage Rates

The triple offset butterfly valve design significantly enhances seal integrity, leading to reduced leakage rates, which is essential in various industrial applications. According to recent studies, leakage rates in conventional butterfly valves can reach as high as 20% under certain conditions. However, triple offset designs can minimize these rates to less than 0.1%, which is a considerable improvement. This remarkable reduction is largely attributed to the unique geometry of the valve, where the offset angles help ensure that the disc does not touch the seat until the valve is fully closed, creating a tighter seal.

Additionally, a report published by the Industrial Valve Association indicates that the use of triple offset butterfly valves can result in operational cost savings due to decreased maintenance and repair requirements associated with leakage. This technology allows for reliable performance even under high pressure and temperature conditions, which is vital for industries such as oil and gas, water treatment, and chemical manufacturing. By utilizing triple offset butterfly valves, companies can not only improve their operational efficiency but also satisfy stringent environmental regulations regarding emissions and leakage.

Durability and Longevity: The Performance of Triple Offset Valves in Harsh Environments

Triple offset butterfly valves are renowned for their exceptional durability and longevity, particularly in harsh industrial environments. Their unique design, which incorporates three distinct offsets, offers significant advantages over traditional valve types. This configuration minimizes wear and tear on the sealing surfaces, allowing these valves to maintain their integrity even when exposed to challenging conditions such as extreme temperatures, high pressures, and corrosive substances. As a result, they are ideal for applications in sectors such as oil and gas, chemical processing, and power generation.

Furthermore, the robust construction of triple offset valves ensures they can handle the rigors of demanding operational scenarios without succumbing to the common issues faced by other valve types, such as leakage or premature failure. The materials used in their fabrication, often resistant to chemical attack and capable of withstanding substantial mechanical stress, contribute significantly to their extended operational lifespan. This reliability not only reduces the need for frequent maintenance but also leads to lower overall lifecycle costs, making them a practical choice for industries striving for efficiency and sustainability in their processes.

Top 10 Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

This chart illustrates the top 10 benefits of using triple offset butterfly valves in industrial applications, highlighting their performance ratings based on key characteristics such as durability, corrosion resistance, and low torque operation. Each benefit is rated on a scale from 1 to 10, showcasing the overall strengths of triple offset valves in harsh environments.

Cost-Effectiveness: Analyzing Long-Term Savings with Triple Offset Valves

The economic advantages of utilizing triple offset butterfly valves in industrial applications extend far beyond their initial purchase price. A recent study from the American Society of Mechanical Engineers (ASME) indicates that these valves can lead to significant long-term savings, primarily due to their enhanced durability and lower maintenance costs. Manufacturers have reported that triple offset valves can last up to 30 years with minimal wear and tear, which is approximately 50% longer than traditional valve types. This longevity translates to reduced frequency of replacements and associated labor costs, potentially saving businesses thousands of dollars over time.

Moreover, the increased efficiency offered by triple offset butterfly valves can result in improved operational performance, which further promotes cost savings. According to a report published by the International Journal of Industrial Engineering, these valves exhibit a leakage rate of less than 0.01% when properly installed and maintained, significantly minimizing energy losses in systems that handle critical fluids and gases. This leak-tight performance not only enhances process efficiency but also reduces environmental compliance costs by lowering the risk of emissions, reinforcing the case for companies to invest in triple offset valves despite their higher upfront costs. Ultimately, the strategic implementation of triple offset butterfly valves serves as a robust solution for organizations aiming to optimize expenditures and enhance operational efficiency in the long run.

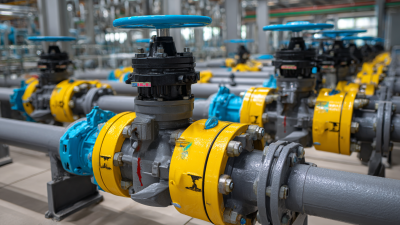

Versatility in Industrial Applications: From Oil and Gas to Water Treatment Systems

Triple offset butterfly valves have gained recognition for their versatility across various industrial applications, particularly in sectors such as oil and gas and water treatment systems. According to a report by Research and Markets, the global valve market is projected to reach $98.27 billion by 2026, driven by industrial growth and the increasing need for efficient fluid control mechanisms. These valves are not only suitable for high-pressure and high-temperature environments, making them indispensable in oil and gas operations, but also provide a tight seal that is critical in water treatment processes to prevent leakage and ensure safety.

In oil and gas applications, the resilience of triple offset butterfly valves allows them to handle corrosive substances and extreme conditions prevalent in upstream activities. A study from the International Energy Agency highlights that effective flow control solutions can reduce operational costs by up to 30%. Meanwhile, in water treatment, the ability of these valves to minimize pressure drops ensures that systems operate at peak efficiency. The Water and Wastewater Equipment Manufacturers Association emphasizes that innovations in valve technology are essential for improving water quality and operational reliability in treatment facilities, reinforcing the strategic role of triple offset butterfly valves in both resource extraction and preservation.

Related Posts

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

-

10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

Understanding the Functionality of Low Pressure Check Valves in Fluid Systems