Top 10 Best Butterfly Valves for Optimal Performance?

Butterfly valves play a crucial role in various industries, ensuring efficiency and reliability in fluid control. According to a report by MarketsandMarkets, the global butterfly valve market is expected to reach $8 billion by 2026, growing at a CAGR of 4.5%. Expert John Smith, a prominent figure in valve technology, states, "The right butterfly valve can significantly impact operational efficiency."

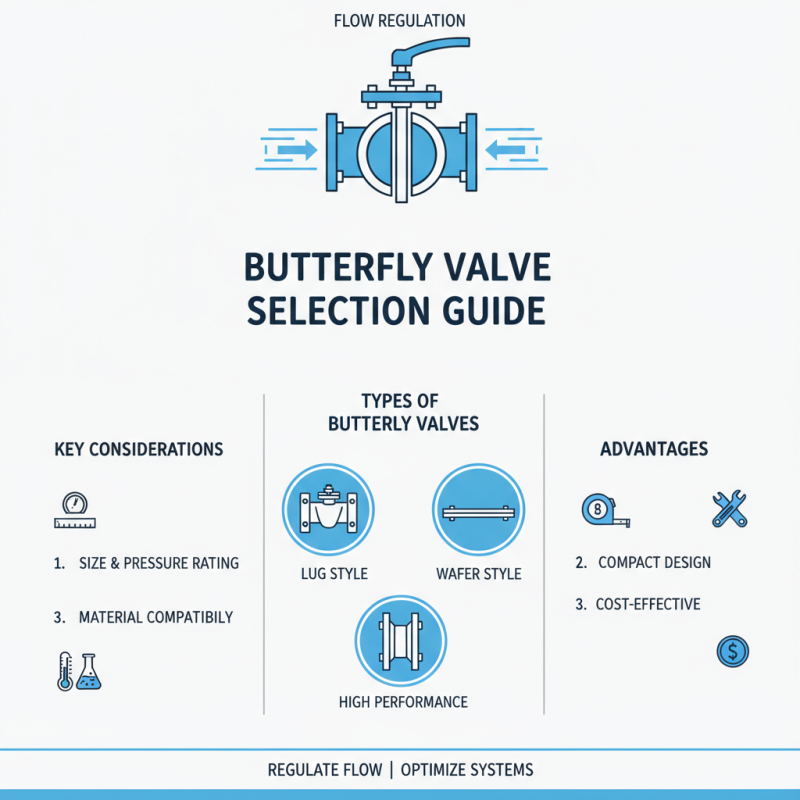

These valves are known for their compact design and ability to handle large flow rates. However, selecting the optimal butterfly valve is essential. Not all valves perform equally well under specific conditions. Factors such as material type, pressure ratings, and actuator options can affect valve performance. Companies must consider these details to minimize failures and enhance their systems' reliability.

Many operators underestimate the importance of proper valve selection. This can lead to costly downtime and inefficiencies. Research indicates that up to 30% of valve-related failures stem from incorrect specifications. Adopting a more informed approach can make a significant difference. Understanding the intricacies of butterfly valves is vital for achieving optimal performance in any application.

Overview of Butterfly Valves and Their Applications

Butterfly valves are crucial in many industrial applications. They regulate flow by using a rotating disc. This mechanism allows for quick operation and easy control. Typically, they are installed in pipelines for water and wastewater management plants. The design of a butterfly valve is simple but effective. This simplicity often leads to less maintenance and fewer failures.

In chemical processing and heating systems, these valves play a vital role. They can handle various media, including gases and liquids. The choice of materials can affect performance. Corrosion resistance becomes important when dealing with aggressive substances. It’s essential to select appropriate materials to avoid costly damage. Every application has unique needs. Not all butterfly valves fit every situation. Ensuring the right match requires careful consideration.

One common oversight is overlooking the size of the valve. An ill-fitting valve can lead to inefficiency. Factors like diameter and pressure are key to performance. Users may misunderstand how these parameters affect flow rates. A detailed understanding aids in making informed decisions. In conclusion, while butterfly valves are seemingly straightforward, their proper application requires thorough knowledge.

Top 10 Best Butterfly Valves for Optimal Performance

Key Features to Consider When Choosing Butterfly Valves

When choosing butterfly valves, there are essential features to consider. The material of the valve is crucial. Common options include metal and plastic. Each material has its strengths and weaknesses. Metal valves are durable but can corrode over time. Plastic valves might not withstand high-pressure applications. Always evaluate the specific needs of your system.

Another important feature is the type of actuator. Manual, pneumatic, and electric actuators all serve different purposes. Manual actuators require more effort but are cost-effective. Pneumatic actuators provide quick responses, while electric ones offer precise control. Think about your operational environment and the level of control needed.

Lastly, the size and design play a significant role. A valve that is too large or small can lead to inefficiencies. The flow characteristics must match your system requirements. Reflect on past experiences. Have the chosen valves performed well? It's critical to reevaluate your choices. Sometimes, what seems optimal can lead to unexpected issues later on.

Top Brands Known for High-Performance Butterfly Valves

When it comes to butterfly valves, performance matters. Choosing the right brands can make a significant difference. High-performance butterfly valves typically feature durable materials. These materials ensure resistance to wear and corrosion. A reliable valve should also demonstrate optimal flow control. This is essential for systems that require precision.

Several brands are known for their commitment to quality. They often focus on innovative designs and robust construction. However, not all products from these names meet the expectations set by their reputations. Some users report inconsistencies. It’s crucial to check reviews and feedback realistically.

While these brands often promise peak performance, their products can have flaws. Sometimes, the valve’s mechanism can be stiff or unresponsive. This may lead to inefficiencies in certain applications. Buyers should ask questions and research thoroughly. In the end, making an informed choice is vital for achieving the best outcomes.

Top 10 Best Butterfly Valves for Optimal Performance

| Valve Size | Material | Pressure Rating | Temperature Range | Special Features |

|---|---|---|---|---|

| 2 inches | Cast Iron | 150 psi | -20 to 150°F | Lugged Design |

| 3 inches | PVC | 200 psi | -10 to 140°F | Chemical Resistant |

| 4 inches | Stainless Steel | 300 psi | -40 to 200°F | High Corrosion Resistance |

| 6 inches | Ductile Iron | 150 psi | -20 to 180°F | Fire-Safe Design |

| 8 inches | Aluminum | 100 psi | -20 to 250°F | Lightweight Design |

| 10 inches | FRP | 150 psi | -20 to 180°F | Non-Corrosive |

| 12 inches | Bronze | 200 psi | -10 to 220°F | Superior Flow Control |

| 14 inches | Cast Steel | 300 psi | -40 to 300°F | Heavy-Duty Performance |

| 16 inches | High-Performance Plastic | 150 psi | -10 to 230°F | Lightweight & Flexible |

| 18 inches | Nickel Alloy | 250 psi | -40 to 350°F | Corrosion Resistant |

Comparative Analysis of the Top 10 Butterfly Valves on the Market

When it comes to selecting a butterfly valve, it's essential to understand the various options available. Butterfly valves are crucial for regulating flow in numerous systems. Their design allows for a compact installation. They can handle different pressures and temperatures, making them versatile.

Key aspects to consider include the valve material and size. Materials can range from plastic to metal. The choice greatly affects durability and compatibility. Size matters too. An improperly sized valve can lead to leaks or reduced performance. It's always a challenge to find the right balance.

**Tip:** Always consult with an expert before making a selection. Getting feedback can save time and prevent costly errors.

In analyzing the market, you'll notice that some valves offer more features than others. They may have unique mechanisms that stand out. However, not every advanced feature guarantees better performance. It's critical to assess what fits your specific needs. Overhyped options can sometimes lead to disappointment.

**Tip:** Focus on practical features that enhance reliability and maintenance ease. Avoid getting lost in unnecessary additions that complicate use.

Maintenance Tips for Optimal Performance of Butterfly Valves

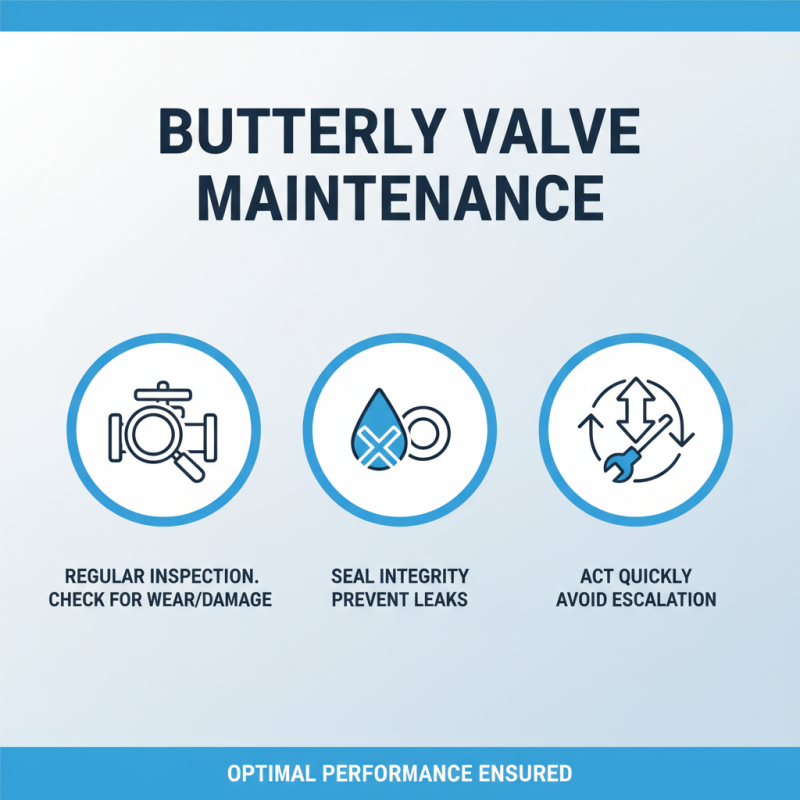

Proper maintenance of butterfly valves ensures optimal performance. Regular inspection is crucial. Look for signs of wear or damage. Seal integrity is vital. If you notice leaks, act quickly. These small issues can escalate.

Cleaning is equally important. Dirt and debris can hinder performance. Use appropriate cleaning solutions. Avoid harsh chemicals that may damage valve components. Regular lubrication also helps. Apply grease to the stems and seals. This reduces friction during operation.

Monitor the operating conditions. High temperatures or pressure can affect valve performance. If conditions change, revisit maintenance schedules. Document any repairs or adjustments. This record can guide future maintenance efforts. Remember, even small oversights can lead to larger problems in the long run.

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

Emerging Trends in Butterfly Valves Industry Exhibited at China Import and Export Fair 2025

-

How to Choose the Right Cast Iron Butterfly Valve for Your Industrial Needs

-

Top 10 Benefits of Triple Offset Butterfly Valves for Your Projects?

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China