How to Choose the Right Industrial Valves for Your Needs?

Choosing the right industrial valves is crucial for efficient operations across various sectors. According to a recent market analysis by Research and Markets, the industrial valves market is projected to reach $97 billion by 2026, reflecting a growing demand. This growth calls for careful selection. With countless options available, it becomes challenging to identify which valves suit specific applications best.

Different industries, from oil and gas to water treatment, depend on industrial valves for operational efficiency. Selecting the wrong type can lead to leaks, pressure drops, and costly shutdowns. Consider factors such as material compatibility and pressure ratings. Suboptimal choices may not only compromise safety but also increase maintenance costs.

Investing in the right industrial valves ensures not just immediate performance, but long-term reliability too. Yet, many companies overlook the criticality of valve selection. Involving experts in the decision-making process can mitigate risks. Reflecting on past choices can reveal areas of improvement. Balancing cost and quality is essential for making sound decisions.

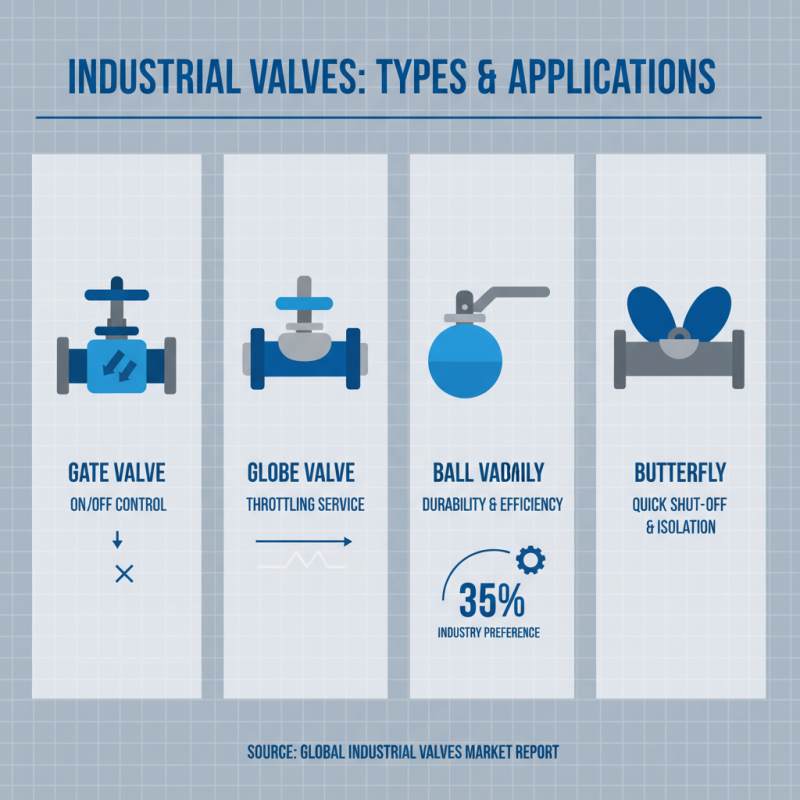

Understanding the Types of Industrial Valves and Their Applications

When selecting industrial valves, it’s crucial to understand the various types available and their specific applications. Common types include gate valves, globe valves, ball valves, and butterfly valves. Each type serves distinct purposes. For instance, gate valves are ideal for on/off control, while globe valves excel in throttling services, according to a report by the Global Industrial Valves Market. This report notes that 35% of industries prefer ball valves for their durability and efficiency.

Applications vary widely across sectors. In oil and gas, for example, valves manage pressures and temperatures. They are crucial for pipeline safety. According to a recent industry survey, 60% of maintenance issues stem from valve malfunctions. This highlights the need for absolute precision in choosing the right type. In water treatment, butterfly valves are favored due to their space-saving design and quick open-close capabilities.

Choosing the right valve isn’t always straightforward. Factors like pressure ratings, material compatibility, and operational environment must be considered. An improperly selected valve can lead to leaks and operational downtime, proving costly for companies. As data shows, 70% of users express dissatisfaction with their current valve configurations. This indicates a need for thorough assessment before making a choice.

Evaluating Key Factors for Selecting Industrial Valves

Choosing the right industrial valves necessitates careful evaluation of several key factors.

Material compatibility is crucial. Different industries use various substances, and each valve material has its limits. For instance, the American Society of Mechanical Engineers (ASME) notes that over 25% of valve failures stem from material incompatibility. Knowing your substance is essential.

Pressure and temperature ranges also play critical roles. Valves must handle specific conditions without failure. According to a recent industry analysis, 43% of valve-related incidents are due to pressure mismanagement. Selecting a valve rated for higher pressures can provide a safety buffer. However, overspecifying can lead to unnecessary costs.

Balancing operational needs with budget constraints is vital.

Flow characteristics should not be overlooked. Flow rate impacts system efficiency. A report from the International Society of Automation suggests that improper valve selection can decrease overall efficiency by 15%. Evaluate the flow patterns required by your system.

Err on the side of caution, as assumptions can lead to costly errors down the line.

Assessing Performance Specifications and Standards for Industrial Valves

Choosing the right industrial valves begins with understanding performance specifications. Each valve type has unique characteristics tailored for specific applications. For instance, pressure ratings dictate how much force a valve can withstand. If you select a valve with inadequate pressure tolerance, it may fail prematurely.

Material selection is another crucial aspect. Valves made of steel, brass, or plastic can behave differently under various conditions. Chemical compatibility is vital too. A valve resistant to corrosion may be needed in a chemical processing plant. However, some users overlook this detail, leading to early degradation of the valve.

Lastly, it’s essential to consider standards. Industry standards ensure safety and performance. Not adhering to these can have severe consequences. Researching relevant standards is time-consuming, yet it's necessary for safety. Overlooking specifications can lead to failures, impacting production. Testing each valve under real-world conditions is recommended, as theoretical performance may not always match reality. Adjusting your selection process based on these factors is key for optimal performance.

Considering Material Compatibility and Environmental Conditions

Choosing the right industrial valves can be daunting, especially when considering material compatibility and environmental conditions. Various industries require specific materials to ensure efficiency and safety. For instance, a report from the Valves and Actuators Market suggests that around 40% of valve failure is attributed to material incompatibility. This shows how vital proper selection is.

When selecting valves, it’s crucial to assess the chemicals they will encounter. Corrosive materials can weaken certain metals. Additionally, extreme temperatures can compromise valve integrity. It’s advisable to reference material data sheets provided by manufacturers and third-party testing.

Tips: Always verify material compatibility with both the fluid and the environment. If in doubt, consult industry experts.

Consider the surrounding conditions as well. Humidity, pressure, and temperature fluctuations can impact valve performance. If installed in a coastal area, corrosion-resistant materials are essential. Regular inspections can prevent unforeseen failures.

Tips: Schedule routine checks and train staff on valve maintenance. Knowledge gaps can lead to costly downtime. Always stay informed about new materials and technologies in the market.

How to Choose the Right Industrial Valves for Your Needs?

| Valve Type | Material Compatibility | Suitable Environmental Conditions | Operating Pressure (bar) | Operating Temperature (°C) |

|---|---|---|---|---|

| Ball Valve | Stainless Steel, PVC | Corrosive Environments | 10-70 | -20 to 80 |

| Gate Valve | Cast Iron, Bronze | Water and Oil Services | 6-40 | 0 to 150 |

| Check Valve | Aluminum, Stainless Steel | Air and Gas Applications | 0-30 | -10 to 60 |

| Globe Valve | Brass, Steel | High-Temperature Services | 5-65 | -20 to 200 |

| Butterfly Valve | Plastic, Ductile Iron | Wastewater Treatment | 1-50 | 0 to 100 |

Making Informed Decisions Based on Cost and Maintenance Requirements

Choosing the right industrial valves requires careful consideration, especially regarding cost and maintenance. Valves are crucial in various applications, and selecting the wrong type can lead to increased expenses over time. Keep in mind that initial purchase prices may not reflect long-term costs.

Tip: Always assess the total cost of ownership. Factor in maintenance and potential downtime. Sometimes, a cheaper valve might require more frequent repairs. Look for materials that suit the environment. Corrosion resistance can lower expense in the long run.

Maintenance is often overlooked. Installing a valve is only part of the solution. Regular checks can prevent unexpected failures. A valve's complexity can affect maintenance needs. Simple designs often require less care.

Tip: Create a maintenance schedule based on your usage. Document all inspections. Lack of records may lead to oversight. An easy-to-maintain valve saves time and money. Analyze your operational demands frequently. This will help you stay ahead of potential issues.

Understanding your operational context is vital. The right choice balances cost and maintenance intricacies. Avoid rushing the selection process. This can lead to miscalculations and greater challenges later. Take the time to evaluate all factors involved.

Cost and Maintenance Requirements of Different Types of Industrial Valves

Related Posts

-

Top 10 Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

-

Understanding Pressure Valves and Their Impact on Industrial Safety

-

Understanding Gas Valves: Essential Guide to Safety and Efficiency in Modern Applications

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Exploring the Future of Actuated Valves: Innovations Shaping the Global Market Growth to $10 Billion by 2028

-

Top 10 Benefits of Triple Offset Butterfly Valves for Your Projects?