How to Choose the Right Stainless Steel Butterfly Valve for Your Needs

Choosing the right stainless steel butterfly valve for your needs is a critical decision that can significantly impact the efficiency and reliability of fluid control systems across various industries. According to a recent report by the Global Valves Market Research, the demand for stainless steel valves is projected to reach a staggering USD 10 billion by 2025, fueled by their corrosion resistance and versatility in handling various media. Achieving optimal performance requires a thorough understanding of the specifications and operational requirements unique to each application.

Industry expert Dr. Jane Smith, a renowned authority on valve technology, emphasizes the importance of selection criteria: "The efficiency of a fluid control system hinges on choosing the appropriate valve type, as it directly affects flow rates and safety standards." In light of this, several factors such as pressure rating, size, and compatibility with the medium must be considered when selecting a stainless steel butterfly valve. Understanding your system's needs will not only enhance operational efficiency but also prolong the lifespan of the valve itself, ultimately contributing to more reliable and cost-effective operations.

Understanding the Basics of Stainless Steel Butterfly Valves

Stainless steel butterfly valves are essential components in various industries, providing efficient flow control and isolation. Their design consists of a disc that pivots within the pipeline, allowing for quick operation and minimal pressure loss compared to other valve types. According to a report by MarketsandMarkets, the global butterfly valve market is projected to reach USD 6.1 billion by 2026, growing at a CAGR of 5.3%. This growth can be attributed to the increasing demand for efficient fluid management in water treatment, oil and gas, and chemical processing.

When selecting a stainless steel butterfly valve, it is crucial to understand the fundamental characteristics that affect their performance in specific applications. The materials used play a significant role; stainless steel offers exceptional resistance to corrosion and high temperatures, making it ideal for harsh environments. Additionally, the valve's size, pressure ratings, and type of actuator (manual, pneumatic, or electric) should align with the requirements of the system in which they will be installed. The 2021 Valve Industry Outlook highlights that industries are increasingly prioritizing automation, influencing the choice of actuators and the design of butterfly valves to enhance operational efficiency and reduce maintenance costs. Understanding these basics will help inform your decision-making process, ensuring that you select the right butterfly valve for your unique needs.

How to Choose the Right Stainless Steel Butterfly Valve for Your Needs

| Feature | Description | Considerations |

|---|---|---|

| Size | Available in various diameters, typically ranging from 1 inch to 48 inches. | Choose based on pipeline size and flow requirements. |

| Material | Commonly made from 304 and 316 stainless steel for corrosion resistance. | 316 stainless steel is preferred for harsh environments. |

| Actuation Type | Manual, pneumatic, or electric actuation options are available. | Choose based on the ease of operation and control required. |

| Pressure Rating | Typically rated for Class 150 to Class 300. | Ensure the valve can handle the system pressure. |

| Temperature Rating | Designed to handle temperatures from -20°F to 400°F. | Confirm compatibility with your application's temperature requirements. |

| Body Style | Wafer, lug, or flanged designs. | Select style based on how the valve fits into your system. |

Key Factors to Consider When Selecting a Butterfly Valve

When selecting a stainless steel butterfly valve, several key factors must be taken into account to ensure optimal performance for your specific application. First and foremost, the valve size and connection type should align with your piping system's specifications. It’s crucial to determine the nominal size of the valve based on the diameter of the pipe it will be installed in, as well as ensuring compatibility with connection methods, such as flanged or weld ends.

Another essential factor is the pressure and temperature rating of the valve. Different applications may expose the valve to varying conditions, so verifying the valve's maximum pressure and temperature ratings is vital to prevent failures. Additionally, consider the valve's sealing mechanism. Depending on the fluid type and the required leak tightness, selecting the appropriate seat material and design—such as rubber or PTFE—can significantly influence the valve's reliability and lifespan. Take into account the environment where the valve will operate, as this can dictate the materials used, especially in corrosive settings. Evaluating these factors will guide you to make an informed choice that meets the demands of your application.

Key Factors to Consider When Selecting a Butterfly Valve

Types of Stainless Steel Butterfly Valves and Their Applications

When selecting a stainless steel butterfly valve, understanding the various types and their specific applications is essential for optimal performance in fluid control systems.

Stainless steel butterfly valves are categorized primarily into three types: resilient seated, metal seated, and high-performance valves.

Resilient seated butterfly valves are commonly used in water applications due to their excellent sealing capabilities and cost-effectiveness. According to industry reports, nearly 40% of global stainless steel valve sales are attributed to this type, making it a preferred choice in municipal water treatment facilities.

Metal seated butterfly valves, on the other hand, are designed for higher temperature and pressure applications, such as in chemical processing industries. These valves are engineered to maintain functionality even under extreme conditions, which is critical for applications involving harsh or abrasive media. The market for metal seated valves is projected to grow by approximately 5% annually due to rising demands in industries requiring durability and reliability.

Finally, high-performance butterfly valves feature advanced designs that provide superior flow control and operational efficiency. These valves are typically used in applications that require precise modulation and are often found in oil and gas as well as power generation sectors. Reports indicate that these valves constitute about 30% of the stainless steel butterfly valve market, reflecting their importance in modern industrial processes where efficiency and control are paramount. Understanding these types and their corresponding applications is crucial for making informed decisions that align with operational requirements.

Sizing and Pressure Ratings for Optimal Performance

When selecting a stainless steel butterfly valve, understanding sizing and pressure ratings is crucial to ensure optimal performance. The size of the valve should correspond to the specific piping system requirements. A valve that is too small may cause significant flow restrictions, while one that is excessively large can lead to turbulence and inefficient operation. Accurately measuring the diameter of the pipe and considering flow rates will help you choose a valve that maintains system efficiency.

Pressure ratings are equally important. Each valve is designed to operate within certain pressure limits, which should align with the pressures experienced in your system. Exceeding these ratings can result in catastrophic failures or leaks. Check the pressure classifications, such as ANSI or ASME standards, to determine the appropriate valve that can withstand your operational conditions.

Tips: Always consult with engineering guidelines or technical documents when sizing valves to obtain precise calculations. Additionally, consider the materials for the valve seals and other components, as these can also impact the pressure ratings and overall durability under specific operating conditions. Lastly, anticipate future changes in your system; opting for a valve with a higher rating than needed can provide flexibility for potential upgrades.

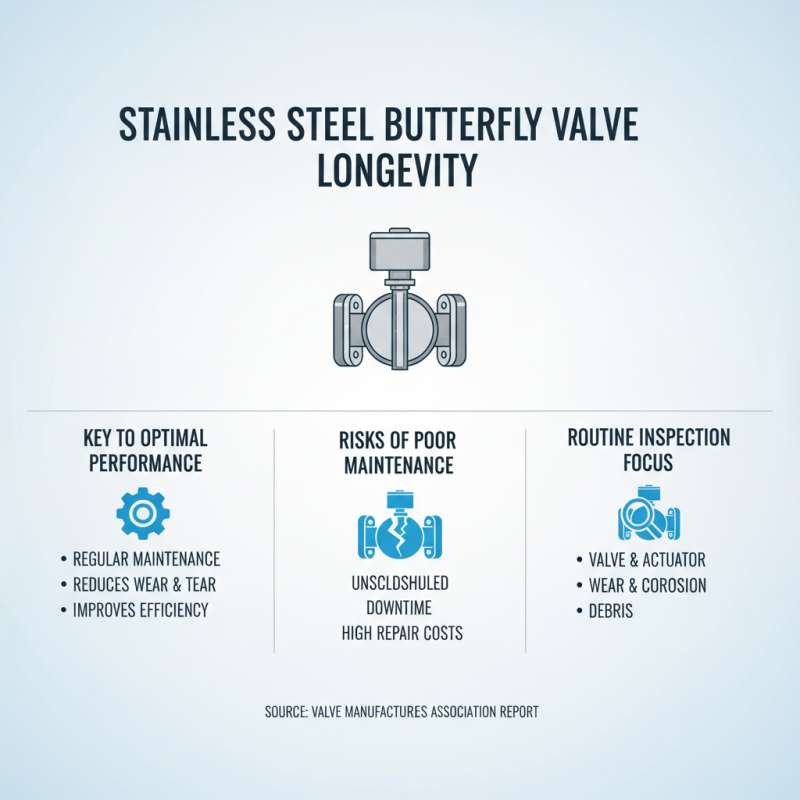

Maintenance and Care Tips for Longevity of Butterfly Valves

Maintaining the longevity of stainless steel butterfly valves is essential for ensuring optimal performance in various applications. Regular maintenance practices can significantly reduce wear and tear, leading to improved efficiency and reduced operational costs. According to a report by the Valve Manufacturers Association, improper maintenance can lead to failures that result in unscheduled downtime, costing industries thousands of dollars each hour. Routine inspections should focus on both the valve and its actuator, checking for signs of wear, corrosion, and debris that might hinder operation.

To extend the lifespan of a butterfly valve, it is crucial to keep the sealing surfaces clean and lubricated as necessary. Industry standards recommend a thorough cleaning every six months, especially in environments that experience heavy particle flow. Additionally, periodic testing for proper pressure ratings and functionality can identify issues before they escalate into major problems. A study conducted by the American Society of Mechanical Engineers highlights that valves maintained on a regular schedule can last up to 30% longer than those that are neglected. By following these maintenance and care tips, operators can ensure their butterfly valves remain reliable components in fluid control systems.

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

Emerging Trends in Butterfly Valves Industry Exhibited at China Import and Export Fair 2025

-

How to Choose the Right Cast Iron Butterfly Valve for Your Industrial Needs

-

10 Essential Tips for Choosing the Right Cast Iron Butterfly Valve for Your Pipeline Systems

-

Understanding Pressure Valves and Their Impact on Industrial Safety