How to Choose the Right Butterfly Valves for Your Application?

Choosing the right butterfly valves for your application is crucial. Butterfly valves play a significant role in various industries, including water treatment, oil and gas, and food processing. According to a report by Market Research Future, the butterfly valves market is expected to reach USD 6.41 billion by 2025. This highlights the growing demand for efficient flow control solutions.

Expert David Johnson, a leading authority in valve technology, emphasizes, “Selecting the right butterfly valves can significantly impact system efficiency.” His insight reflects the intricate balance of performance and durability in valve selection. The failure to choose appropriate valves can lead to leaks and operational inefficiencies, which are costly for businesses.

Understanding the specifications, such as size and material, is critical. Material choices can affect corrosion resistance, especially in harsh environments. However, many overlook the importance of proper installation and maintenance, which can greatly affect valve longevity. As industries evolve, so too must our approach to selecting butterfly valves. Reflection on these factors will lead to better decision-making and improved operational outcomes.

Understanding Butterfly Valve Types and Their Functions

Butterfly valves are essential in various industries. Different types cater to specific functions. Some common butterfly valve types include centric, double eccentric, and triple eccentric valves. Each type offers unique advantages based on the application it serves.

Centric butterfly valves are simple and cost-effective. They suit systems with low-pressure and temperature variations. However, they may not perform well under extreme conditions. Conversely, double eccentric valves provide better sealing and improved performance under higher pressures. They are ideal for industrial applications but may require more maintenance.

When selecting a butterfly valve, consider the operating conditions. Pay attention to factors like pressure, temperature, and medium type.

Tips: Always check the material compatibility with the fluid. This prevents future leaks and failures. Remember, the right choice can save you time and money in the long run. Also, don’t overlook the size of the valve. An improperly sized valve can lead to inefficiencies.

Evaluating Material Compatibility for Butterfly Valve Applications

Choosing the right butterfly valve involves understanding material compatibility. Different applications require specific materials to ensure effectiveness and longevity. For instance, a valve used in water applications may not work well with corrosive chemicals.

Materials like stainless steel, PVC, and rubber each come with their advantages and disadvantages. Stainless steel is durable but can be expensive. PVC is cost-effective but may not endure high temperatures. Rubber gaskets can wear out over time, leading to leaks. Assessing the environment is crucial; sometimes, the wrong material leads to frequent replacements.

Considering temperature and pressure ratings is vital too. High pressures demand stronger materials. Neglecting to check these ratings may result in valve failure. A thorough analysis of the fluid being handled is necessary. Different fluids may interact with materials in unexpected ways. Always reflect on potential reactions that could damage the valve or the system.

Determining the Right Size and Pressure Rating for Valves

Choosing the right butterfly valves involves understanding size and pressure ratings. The size of your valve impacts flow capacity. It is crucial to match the valve size with your piping system to ensure optimal performance. A valve that is too small may restrict flow. Conversely, one that is too large can lead to inefficiency and turbulence.

Pressure ratings determine how much pressure a valve can safely handle. This is essential for system safety and reliability. High-pressure applications require valves designed to withstand higher ratings. Always check the operational conditions of your application. This knowledge will prevent potential failures or accidents.

Tips: Assess your piping layout before selecting a valve. Consider future expansion needs. Consult with engineers for accurate size estimations. If you find it challenging to gauge pressure, don’t hesitate to ask for professional advice. Remember, the right valve ensures system efficiency and longevity. Missteps in selection could lead to costly repairs and downtime.

Butterfly Valve Size and Pressure Ratings

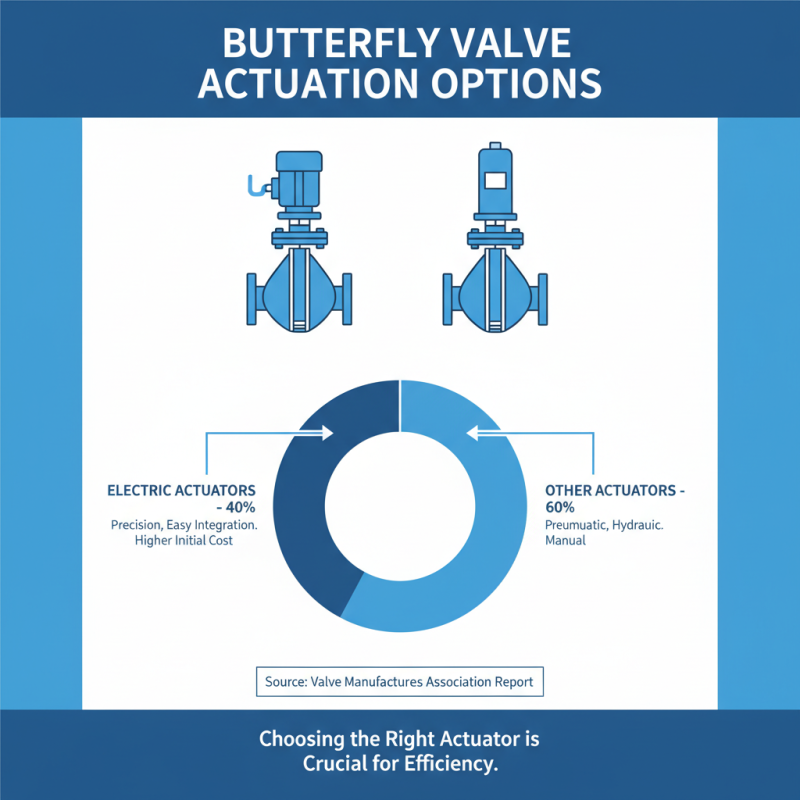

Assessing the Actuation Options for Butterfly Valves

When selecting butterfly valves, understanding actuation options is crucial. Actuators provide the necessary force to operate these valves efficiently. A report by the Valve Manufacturers Association indicates that electric actuators hold a significant market share, accounting for around 40% of overall actuators used in industrial applications. Their precision and ease of integration make them popular. However, their higher initial costs can be a drawback for some applications.

Pneumatic actuators are another option worth considering. They are widely used due to their fast response and reliability in various conditions. Estimates suggest that almost 35% of applications prefer pneumatic over electric actuators due to lower procurement costs. One should question if lower costs compromise performance and long-term durability.

Hydraulic actuators are also available, yet they typically involve more complexity and risk of leaks. In industries such as oil and gas, where pressure is critical, they are often preferred. Still, the energy consumption and maintenance required can be extensive. Evaluating these factors, alongside specific application requirements, can lead to better decisions. Is the focus on cost-effective solutions overshadowing performance reliability?

Considering Installation and Maintenance Requirements for Valves

When selecting butterfly valves, consider the installation and maintenance needs. These valves can differ in design and complexity. More complex valves may require specialized tools for installation. Make sure your team is equipped and trained for the task.

Tips: Always check the valve's weight and size. Ensure your installation space can accommodate it. Heavy valves might need additional support. Plan for easy access to valves for maintenance tasks.

Maintenance is crucial for optimal performance. Regular checks will prevent leaks and other failures. A valve that’s hard to reach can lead to neglect. This might result in costly repairs down the line.

Tips: Document your maintenance schedule. This helps in tracking valve performance over time. Keep spare parts ready, as they can reduce downtime significantly.

Related Posts

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

Top 10 Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control