Why Electric Valves are Essential for Efficient Fluid Control Systems

In the evolving landscape of fluid control systems, electric valves have emerged as a pivotal element in enhancing efficiency and precision across various industries. According to a recent report by MarketsandMarkets, the global electric valve market is projected to reach USD 12.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.3% from 2020. This surge is primarily driven by the need for advanced automation technologies and the growing demand for smart solutions in sectors like oil and gas, water treatment, and chemical processing.

Industry expert Dr. Emily Carver, a leading authority in hydraulic systems, emphasizes the critical role that electric valves play in modern fluid management. She states, “The integration of electric valves into fluid control systems not only streamlines operations but also significantly reduces energy consumption, paving the way for greener and more sustainable industrial practices.” Such insights underscore the necessity of incorporating electric valves to meet regulatory standards and operational efficiency targets, making them indispensable in today’s competitive market.

As we explore the top trends and innovations shaping the electric valves sector in 2025, it becomes clear that investing in this technology is not just an operational upgrade but a strategic advantage for companies aiming to lead in fluid control systems.

Key Advantages of Electric Valves in Fluid Control Systems

Electric valves have emerged as crucial components in modern fluid control systems, offering significant advantages over traditional mechanical valves. One of the primary benefits is their ability to provide precise control over fluid flow. According to a report by the International Society of Automation, systems utilizing electric valves can achieve flow accuracy improvements of up to 30%, resulting in better process control and reduced resource waste. This enhanced precision is particularly valuable in applications ranging from water treatment to chemical processing, where even slight variations can lead to costly inefficiencies.

Moreover, electric valves are often praised for their rapid response times, allowing for quicker adjustments as system demands change. Data from the Fluid Controls Industry indicates that electric valves can respond up to three times faster than their pneumatic counterparts, which is essential in dynamic environments. The integration of automation technology also facilitates remote monitoring and operation, reducing the need for manual intervention and enhancing overall operational safety.

Tip: When selecting electric valves for your system, consider models with built-in feedback systems to ensure you can monitor performance in real-time and make data-driven adjustments. Also, look for valves with durable materials to extend their lifespan, especially in corrosive or high-pressure applications.

How Electric Valves Enhance System Efficiency and Performance

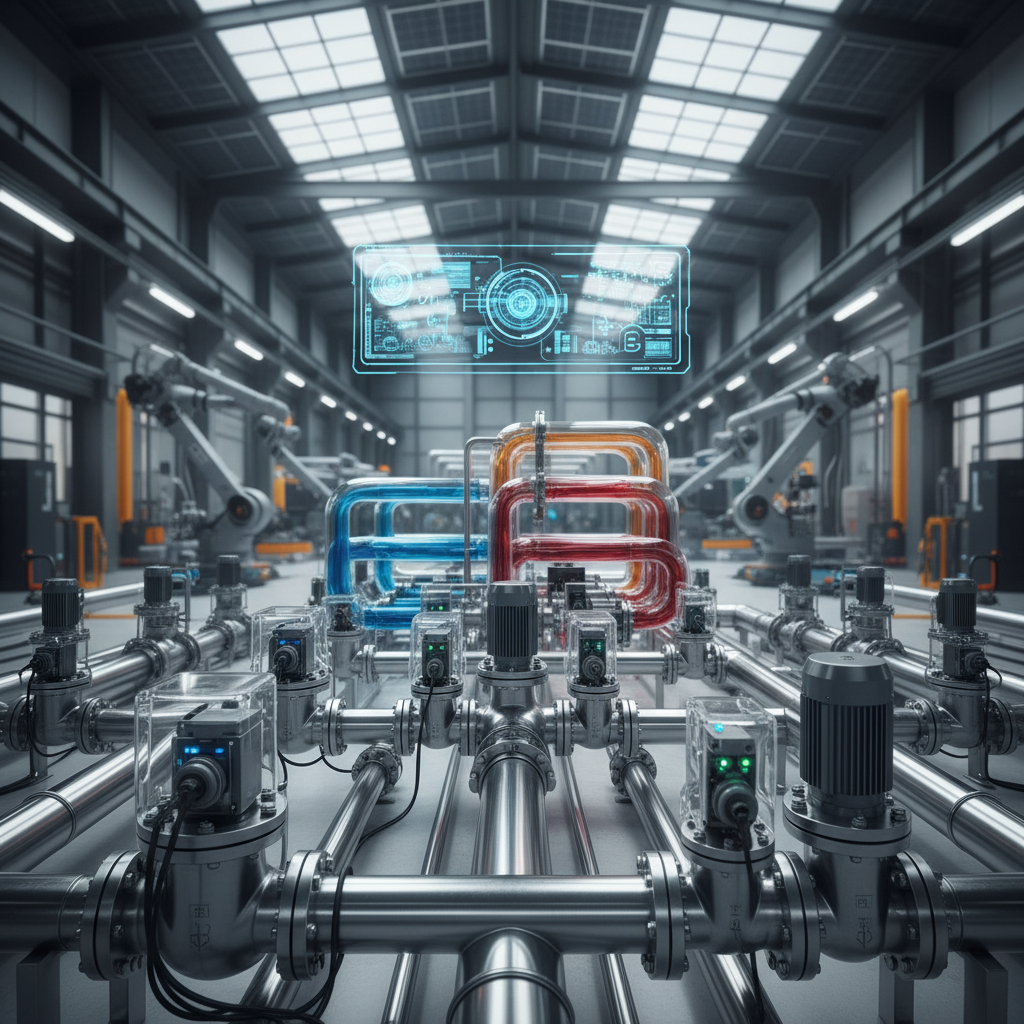

Electric valves play a crucial role in enhancing the efficiency and performance of fluid control systems. By offering precise control over the flow of fluids, these valves reduce energy consumption and minimize wastage. Their ability to operate automatically allows for seamless integration into smart systems, optimizing processes in various applications, from manufacturing to water treatment. This precision not only improves system response times but also enhances overall safety by minimizing the risks associated with overflows or leaks.

Electric valves play a crucial role in enhancing the efficiency and performance of fluid control systems. By offering precise control over the flow of fluids, these valves reduce energy consumption and minimize wastage. Their ability to operate automatically allows for seamless integration into smart systems, optimizing processes in various applications, from manufacturing to water treatment. This precision not only improves system response times but also enhances overall safety by minimizing the risks associated with overflows or leaks.

Tips for maximizing the efficiency of electric valves include regular maintenance checks to ensure optimal performance and investing in smart control systems that can monitor valve operation in real time. Additionally, using electric valves in tandem with flow meters can provide valuable data for adjusting operations, ultimately leading to enhanced system responsiveness and stability. Regular training for operators on the latest technologies can also significantly improve the handling and operating of these systems, further boosting performance.

Integration of Electric Valves in Modern Industrial Applications

The integration of electric valves in modern industrial applications has revolutionized fluid control systems by enhancing precision and efficiency. These valves utilize electrical signals to automate the opening and closing process, allowing for real-time adjustments in flow rates and pressure. This automation reduces the need for manual intervention, leading to increased productivity and minimized human error. Electric valves are particularly beneficial in environments where rapid response to changing conditions is critical, such as in chemical processing or food production.

Moreover, electric valves contribute to improved system reliability and maintenance. Equipped with diagnostic features, they can provide critical data regarding the operational status and potential issues, enabling proactive maintenance strategies. This predictive capability not only extends the lifespan of the valves but also minimizes downtime, which is essential in high-stakes industries. As industries continue to adopt smart technologies and IoT solutions, the role of electric valves in fluid control systems will only become more significant, paving the way for smarter, more efficient industrial processes.

Comparative Analysis: Electric Valves vs. Traditional Valve Types

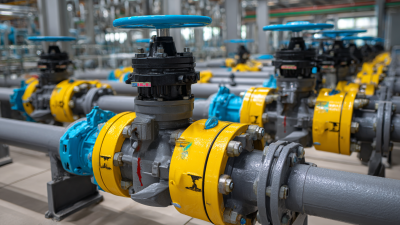

When comparing electric valves to traditional valve types such as pneumatic and manual valves, several key differences emerge that highlight the advantages of electric valves in fluid control systems. Electric valves offer precise control over flow rates, allowing for real-time adjustments that can be automated through control systems. This capability not only enhances operational efficiency but also improves responsiveness to shifts in system demands, whereas traditional valves often rely on mechanical manipulation, which can be slower and less accurate.

Additionally, electric valves require less physical effort to operate, which reduces the risk of operator fatigue and errors associated with manual handling. Pneumatic valves, while effective, necessitate a compressed air supply and can be affected by fluctuations in air pressure, leading to inconsistent performance. In contrast, electric valves maintain consistent functionality without such dependencies, further underlining their reliability. The integration of electric valves into fluid control systems results in reduced maintenance requirements and lower energy consumption, establishing them as a superior choice for modern applications.

Why Electric Valves are Essential for Efficient Fluid Control Systems

| Feature | Electric Valves | Traditional Valves |

|---|---|---|

| Response Time | Fast (milliseconds) | Slow (seconds) |

| Control Precision | High | Moderate |

| Energy Efficiency | High | Low |

| Maintenance Requirements | Low | High |

| Installation Complexity | Moderate | Simple |

| Cost | Moderate | Low |

Future Trends in Electric Valve Technology for Fluid Management

As the demand for efficient fluid management systems grows, electric valve technology is evolving rapidly. According to a report by MarketsandMarkets, the electric valve market is projected to reach $4.89 billion by 2026, growing at a CAGR of 5.6%. This trend is driven by the increasing need for automation and precise control in industries ranging from water treatment to manufacturing. Electric valves offer significant advantages, including reduced energy consumption and enhanced reliability compared to traditional pneumatic and hydraulic valve systems.

Future trends indicate a shift towards smart electric valves equipped with IoT capabilities. These innovations allow for real-time monitoring and remote control, leading to improved operational efficiency. Data from Allied Market Research highlights that the smart valve segment is expected to grow at a remarkable rate due to its integration with advanced analytics and artificial intelligence. Companies that adopt these technologies will benefit from increased agility, optimizing maintenance schedules and minimizing downtime.

**Tip:** When selecting electric valves, consider those with advanced diagnostics capabilities. This ensures proactive maintenance, ultimately saving time and costs in the long run. Additionally, prioritize valves that offer compatibility with existing control systems to streamline integration. Implementing these measures will enhance the efficiency of your fluid management systems.

Related Posts

-

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs

-

Essential Control Valves Maintenance Checklist for Optimal Performance

-

Understanding Pressure Valves and Their Impact on Industrial Safety

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

-

Exploring the Future of Actuated Valves: Innovations Shaping the Global Market Growth to $10 Billion by 2028

-

Understanding the Functionality of Low Pressure Check Valves in Fluid Systems