Understanding the Future of Automated Valves in Modern Industry Technology

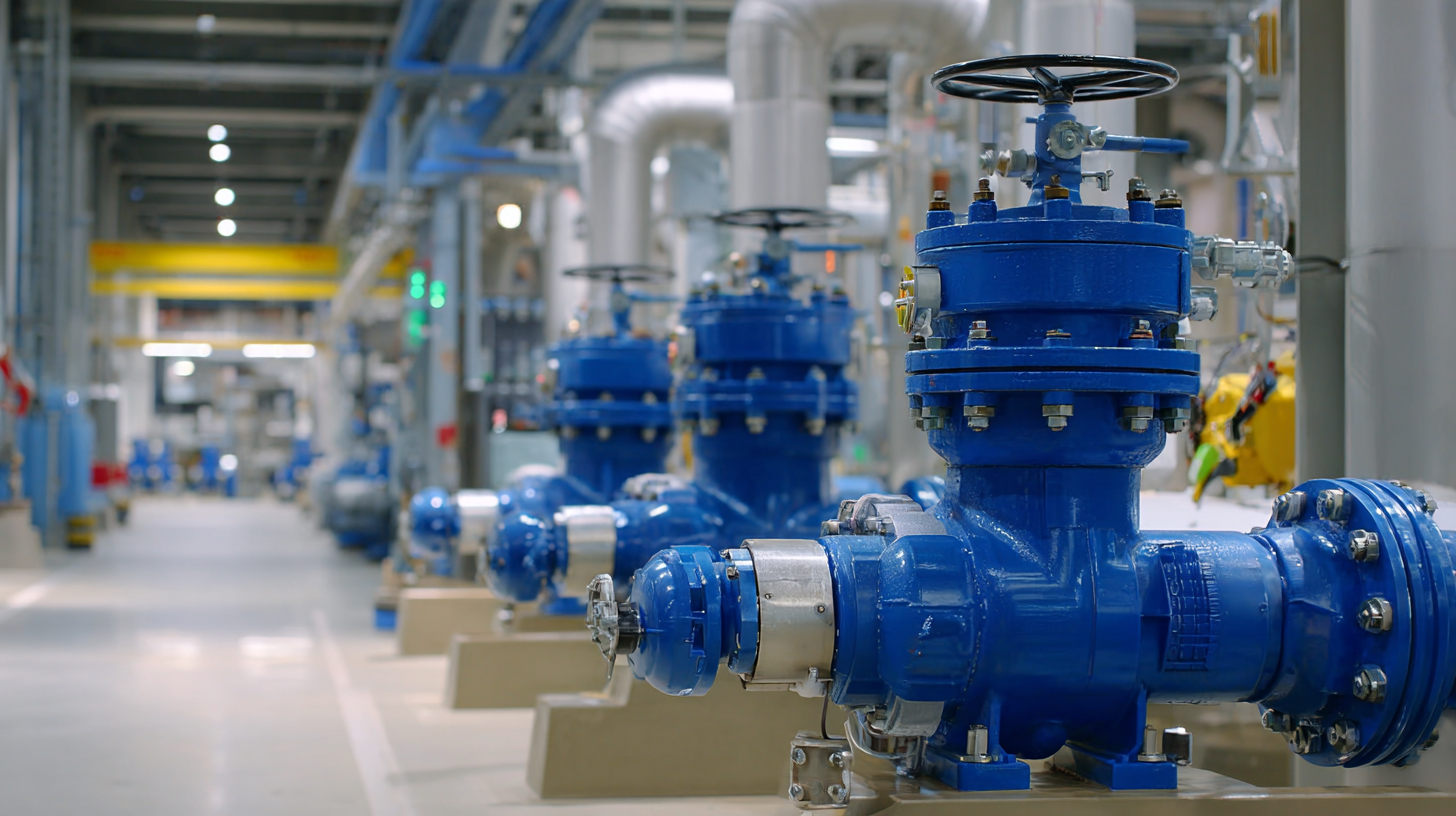

In the rapidly evolving landscape of modern industry, automated valves are becoming increasingly crucial for enhancing operational efficiency and safety. As sectors such as oil and gas, water treatment, and manufacturing demand more sophisticated control systems, understanding the future of these technologies is essential for stakeholders looking to stay competitive.

This article will explore how to leverage automated valves effectively, highlighting their design principles, the integration of advanced sensors and control systems, and the role of artificial intelligence in predictive maintenance.

By delving into the latest innovations and best practices, we aim to provide a comprehensive guide that equips industry professionals with the knowledge to optimize their processes and embrace the benefits that automated valves offer. As automation continues to reshape industrial operations, staying informed about these developments is key to harnessing their full potential.

The Role of Automated Valves in Enhancing Industrial Efficiency

Automated valves play a pivotal role in boosting industrial efficiency across various sectors, including oil and gas, water treatment, and manufacturing. According to a report by MarketsandMarkets, the automated valve market is projected to reach $10.2 billion by 2025, driven by the increasing demand for process optimization and operational reliability. These valves enhance efficiency by enabling precise control over fluid and gas flows, reducing waste, and minimizing human error. As industries embrace automation, the integration of smart valve technology allows for real-time monitoring and data analysis, further streamlining operations.

Tips: When implementing automated valves, consider investing in advanced control systems that can provide predictive maintenance alerts. This proactive approach helps in avoiding unplanned downtime, ultimately saving both time and costs.

Moreover, the use of automated valves contributes significantly to energy savings and sustainability. A study by the Energy Efficiency Standards (EES) revealed that adopting automated valve solutions in industrial processes can lead to an energy reduction of up to 30%. This not only supports environmental goals but also enhances the bottom line, making automated valves an essential investment for modern industries striving for efficiency and sustainability.

Tips: Conduct a thorough energy audit to assess the potential savings that automated valves can bring to your operations, and choose valves equipped with energy-efficient features to maximize returns.

Key Technologies Driving the Evolution of Automated Valves

The evolution of automated valves in industrial technology is primarily driven by advancements in several key technologies. Prominent among these are the integration of IoT (Internet of Things) capabilities and artificial intelligence, which provide real-time data analysis and enhanced decision-making processes. According to a report by MarketsandMarkets, the global automated valve market is projected to grow from USD 2.9 billion in 2020 to USD 5.6 billion by 2025, indicating a compound annual growth rate (CAGR) of 14.5%. This rapid growth can be attributed to the increasing demand for automation and control systems in industries such as oil and gas, water treatment, and chemical processing.

Moreover, emerging technologies such as machine learning and predictive maintenance are enhancing the functionality of automated valves. By harnessing these technologies, industries can reduce downtime and improve operational efficiency. A report by ResearchAndMarkets highlights that predictive maintenance solutions can potentially reduce equipment failures by 30% to 40%, leading to significant cost savings. As industries continue to prioritize efficiency and safety, the role of automated valves, augmented by these advanced technologies, is becoming more crucial than ever in modern industrial applications.

Understanding the Future of Automated Valves in Modern Industry Technology

| Technology | Description | Benefits | Application Areas |

|---|---|---|---|

| IoT Integration | Utilizing Internet of Things technology for real-time monitoring and control. | Enhanced efficiency and predictive maintenance. | Manufacturing, Oil & Gas, Water Treatment. |

| Artificial Intelligence | AI algorithms to optimize valve performance and decision-making. | Reduced downtime and improved system reliability. | Energy Management, Process Automation. |

| Remote Operation | Controls and monitors valves remotely for accessibility. | Improved safety and reduced personnel exposure. | Chemical Processing, HVAC Systems. |

| Energy Harvesting | Using devices that harvest energy from their environment to function. | Reduced energy costs and sustainable operations. | Water Distribution, Renewable Energy Systems. |

Benefits of Integrating Smart Valves in Modern Manufacturing

The integration of smart valves into modern manufacturing systems presents a transformative approach to enhancing operational efficiency. These automated valves utilize advanced sensors and control systems to facilitate real-time monitoring and adjustment, significantly reducing the margin of error associated with traditional manual valve operation. By streamlining processes and ensuring precise control over fluid dynamics, manufacturers can achieve higher productivity and reliability.

Moreover, smart valves contribute to enhanced safety and maintenance protocols. Their ability to provide data analytics allows for predictive maintenance, reducing unexpected downtime and lowering operational costs. This proactive approach not only extends the lifespan of equipment but also minimizes the risk of accidents arising from valve failure.

As industries increasingly prioritize sustainability, integrating smart valves enables better resource management, leading to reduced waste and energy consumption. Overall, the adoption of these advanced technologies positions manufacturers to remain competitive in a rapidly evolving industrial landscape.

Challenges and Solutions in Adopting Automated Valve Systems

The adoption of automated valve systems in modern industry technology presents a unique set of challenges. One primary concern is the integration of these systems with existing infrastructure. Many facilities rely on older mechanical valves, which may not be compatible with newer automated technology. This can lead to significant costs associated with retrofitting or replacing current equipment. Furthermore, there is often a lack of skilled personnel who understand both the operational and maintenance requirements of automated systems, hindering their effective implementation.

**Tip:** To ease the integration process, consider conducting a thorough assessment of your current valve system and identifying areas where automation can deliver the most value. Engaging with a technology consultant can also help in creating a tailored approach for your facility.

Another challenge lies in ensuring cybersecurity for automated valve systems. As these systems become more interconnected, they also become more vulnerable to cyber threats. Implementing rigorous security protocols and maintaining regular software updates are critical to protecting sensitive operations from potential breaches.

**Tip:** Establish a comprehensive cybersecurity strategy that includes employee training, network security measures, and regular system audits to minimize risks associated with automated systems. This proactive approach will help safeguard both your equipment and sensitive data.

Future Trends: Innovations Shaping Automated Valve Technologies

The landscape of automated valve technology is witnessing transformative innovations that promise to redefine operational efficiency and reliability across various industries. One of the most significant trends is the integration of the Internet of Things (IoT) and smart sensors into valve systems. These advancements enable real-time monitoring and predictive maintenance, allowing operators to anticipate issues before they escalate, thereby reducing downtime and operational costs. By harnessing data analytics, industries can optimize valve performance and enhance their overall process efficiency.

Another crucial innovation shaping the future of automated valves is the development of advanced materials and manufacturing techniques. Lightweight, corrosion-resistant materials are being introduced, which not only improve valve longevity but also reduce energy consumption during operation. Furthermore, 3D printing technology is revolutionizing how valves are designed and produced, enabling customization and shorter lead times. This adaptability ensures that industries can rapidly respond to changing demands while maintaining high safety standards and performance reliability. As these trends continue to evolve, automated valves are poised to play a pivotal role in advancing modern industrial technologies.

Related Posts

-

Exploring the Future of Actuated Valves: Innovations Shaping the Global Market Growth to $10 Billion by 2028

-

Essential Control Valves Maintenance Checklist for Optimal Performance

-

How to Optimize Your System Efficiency with Automated Valves

-

Common Issues Faced by Gate Valves in High Pressure Applications

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability