Understanding Gas Valves: Essential Guide to Safety and Efficiency in Modern Applications

In the realm of modern applications, gas valves play a crucial role in ensuring both safety and efficiency in various industries. The global gas valve market is expected to reach approximately $7 billion by 2027, growing at a CAGR of 4.5% from 2020 to 2027, according to industry reports. This growth is largely driven by advancements in technology and the increasing demand for energy-efficient systems. Proper understanding and selection of gas valves can significantly influence operational safety, as improper usage can lead to leaks, malfunctions, or even catastrophic failures. As industries strive to optimize performance while adhering to strict safety standards, a comprehensive knowledge of gas valves, including their types, applications, and maintenance practices, becomes essential. This guide aims to equip professionals with key insights and practical tips to enhance the safety and efficiency of gas valve use in diverse settings.

The Importance of Gas Valve Selection for Safety in Residential Applications

The selection of gas valves is crucial for ensuring safety in residential applications. Gas valves act as the first line of defense against leaks, malfunctions, and potential hazards associated with gas appliances. When selecting a gas valve, homeowners must consider factors such as the type of gas being used, the pressure requirements, and the specific function the valve will serve. Proper valve selection not only protects inhabitants from dangerous situations but also influences the overall efficiency of gas systems, affecting both performance and utility costs.

Additionally, it’s vital for homeowners to consult with professionals when choosing gas valves, as improper selection can lead to severe consequences. A valve that is too small may restrict flow and cause appliances to underperform, while an excessively large valve could fail to close properly, leading to leaks. Regular maintenance and inspections of gas valves are also key to ensuring their longevity and functionality. By prioritizing the correct selection and ongoing care of gas valves, residents can significantly enhance safety and efficiency in their homes.

Analyzing the Role of Gas Valves in Industrial Efficiency and Cost Reduction

Gas valves play a crucial role in enhancing industrial efficiency and promoting cost reduction across various applications. By regulating the flow and pressure of gas, these valves ensure optimal performance in manufacturing processes. The precise control provided by gas valves minimizes wastage and energy consumption, allowing industries to streamline their operations. This results in notable reductions in operational costs, which is particularly important in competitive markets where profit margins are tight.

Gas valves play a crucial role in enhancing industrial efficiency and promoting cost reduction across various applications. By regulating the flow and pressure of gas, these valves ensure optimal performance in manufacturing processes. The precise control provided by gas valves minimizes wastage and energy consumption, allowing industries to streamline their operations. This results in notable reductions in operational costs, which is particularly important in competitive markets where profit margins are tight.

Moreover, modern gas valves are designed with advanced materials and technologies that enhance their durability and reliability. This not only improves safety—mitigating the risk of leaks and explosions—but also reduces maintenance needs, further contributing to cost savings. Industries that adopt high-quality gas valves can experience extended equipment lifespans and decreased downtime, leading to a more efficient and responsive production environment. As a result, the strategic implementation of gas valves becomes a key factor in achieving business sustainability and operational excellence in today’s industrial landscape.

Understanding the Different Types of Gas Valves and Their Specific Uses

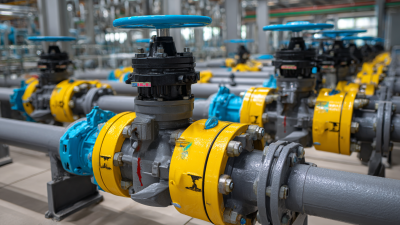

Gas valves play a crucial role in managing the flow of gas in various modern applications. Understanding the different types of gas valves—such as ball valves, gate valves, and globe valves—is essential for ensuring both safety and efficiency in operations. According to a report by the Global Gas Valve Market Analysis, ball valves hold approximately 45% of the market share due to their reliability and quick-operation features. Ball valves are ideal for applications that require tight shut-off, making them suitable for both residential and industrial settings.

On the other hand, gate valves are commonly used in systems where minimal flow restriction is important. They are particularly advantageous in high-pressure situations, as they allow for full flow when wide open. The same market analysis indicates that the demand for gate valves has surged by 27% over the past three years, primarily driven by the oil and gas industry, where efficient flow control is critical. Similarly, globe valves, which are known for their throttling capabilities, are increasingly utilized in heating systems and chemical processes, facilitating better control over fluid dynamics. Understanding the specific uses and advantages of these various gas valves is essential for optimizing performance and ensuring safety in any gas-handling system.

Key Safety Standards and Regulations Governing Gas Valve Usage Today

When dealing with gas valves, understanding the key safety standards and regulations is paramount for ensuring safe and efficient operation. Regulations such as the American National Standards Institute (ANSI) and the National Fire Protection Association (NFPA) provide essential frameworks that govern the design, installation, and maintenance of gas valves. These standards are designed to minimize risks associated with gas leaks, pressure failures, and other hazards, thereby protecting both users and the environment.

Moreover, compliance with these regulations necessitates regular inspections and testing of gas valves to ensure they function effectively under varying conditions. Manufacturers and operators must adhere to guidelines that specify materials, pressure ratings, and operational protocols, all of which contribute to overall system reliability. In addition, local and national codes, such as the International Fuel Gas Code (IFGC), mandate specific practices that further safeguard against potential failures. By remaining informed about these regulations, stakeholders can enhance safety measures while optimizing the efficiency of gas systems across modern applications.

Understanding Gas Valves: Essential Guide to Safety and Efficiency in Modern Applications

| Dimension | Value |

|---|---|

| Operating Pressure (psi) | 300 psi |

| Temperature Range (°F) | -20 to 150 °F |

| Flow Rate (CFM) | 500 CFM |

| Leakage Rate | 0.01 SCFH |

| Construction Material | Brass |

| Safety Standards | ASTM F1972 |

Innovations in Gas Valve Technology: Enhancing Performance and Reliability

Innovations in gas valve technology have significantly enhanced both performance and reliability in modern applications. The latest advancements include the integration of smart technology, which allows for real-time monitoring and control of gas flow. These smart gas valves utilize sensors that detect pressure and flow rates, enabling automatic adjustments to optimize performance and reduce the risk of leaks or malfunctions. This not only ensures safety but also contributes to improved energy efficiency, making them an ideal choice for both residential and industrial settings.

Additionally, materials science has played a crucial role in the development of more durable gas valves. Innovative materials resistant to corrosion and wear extend the lifespan of these components, ensuring consistent performance even under extreme conditions. Advanced sealing technologies also minimize gas leakage, addressing one of the critical safety concerns associated with gas applications.

As the industry continues to evolve, these technological advancements will support the growing demand for safer and more efficient gas management systems, solidifying the importance of reliable gas valve technology in the modern world.

Related Posts

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

Understanding the Functionality of Low Pressure Check Valves in Fluid Systems

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

-

Understanding Pressure Valves and Their Impact on Industrial Safety

-

Understanding the Future of Automated Valves in Modern Industry Technology

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries