Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs

In today's industrial landscape, the selection of the right electric valves is crucial for optimizing process efficiency and ensuring safety. According to a report by MarketsandMarkets, the global electric valve market is projected to reach USD 7.8 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth is driven by the increasing adoption of automation in various industries, including oil and gas, water treatment, and chemical processing. As the demand for precision in controlling fluid flow escalates, understanding the distinct types and functionalities of electric valves becomes essential for engineers and decision-makers. In this ultimate guide, we will explore the key considerations and expert tips for selecting the most suitable electric valves to meet your specific industrial needs, ensuring enhanced operational performance and reliability.

Common Issues Encountered When Selecting Electric Valves

When selecting electric valves for industrial applications, several common issues can arise that may affect performance and reliability. One of the primary concerns is valve compatibility with the fluid in the system. For example, valves made from inferior materials may corrode when handling aggressive fluids, leading to leaks or failures. According to recent findings, proper material selection can result in a significant reduction in maintenance costs and downtime, as improperly chosen valve materials can account for as much as 30% of repair expenses in fluid systems.

Another critical factor to consider is the valve's response time and control precision, which are essential for efficient process management. For instance, a study indicated that electric valves with advanced control mechanisms can enhance energy efficiency by 25-50% in pumping systems, directly impacting overall operational costs. Additionally, common issues such as actuator malfunctions or wiring problems can hinder their effectiveness, making it vital to put thorough testing and quality assurance measures in place during the selection and installation process. Understanding these common pitfalls ensures a more successful integration of electric valves into industrial systems, ultimately enhancing productivity and reliability.

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs - Common Issues Encountered When Selecting Electric Valves

| Criteria | Common Issues | Possible Solutions |

|---|---|---|

| Size and Type | Mismatched sizes leading to leaks | Ensure accurate measurements and consult specifications |

| Voltage Compatibility | Incompatible voltage may cause malfunctions | Check voltage ratings and select appropriately |

| Material Selection | Corrosion or wear due to unsuitable materials | Select materials based on fluid characteristics |

| Control Type | Complexity in control system integration | Evaluate control options and engineer compatibility |

| Maintenance Requirements | High maintenance needs may increase downtime | Select low-maintenance models or improve maintenance schedules |

| Environmental Conditions | Temperature fluctuations affecting performance | Choose valves rated for specific environmental conditions |

Understanding Different Types of Electric Valves for Industrial Applications

When selecting electric valves for industrial applications, understanding the different types available is essential for optimizing operational efficiency. Electric valves can be broadly categorized into two main types: globe valves and ball valves. According to a recent market research report by MarketsandMarkets, the ball valve segment is expected to grow at a CAGR of 6.1% from 2021 to 2026, driven by its efficiency in fluid control and quick operation. Globe valves, on the other hand, are often favored for their throttling capabilities, particularly in applications requiring precise flow regulation.

Another critical aspect to consider is the actuator type. Electric actuators, including on/off and modulating types, are widely used in industries ranging from water treatment to oil and gas. A study by Grand View Research indicates that the global electric valve actuator market is projected to witness substantial growth, reaching USD 2.82 billion by 2025, fueled by advancements in technology and increasing demand for automation. Selecting the right actuator type can greatly enhance the performance of electric valves, making it vital for industrial operators to assess their unique system requirements carefully.

Key Factors to Consider in Electric Valve Performance

When selecting electric valves for industrial applications, the performance of the valve is a critical aspect that cannot be overlooked. One of the key factors to consider is the valve's response time. In fast-paced industries, valves that can quickly adjust to changing conditions enhance operational efficiency and minimize downtime. It’s essential to assess the actuator speed and ensure it aligns with the system requirements, as even minor delays can lead to significant process inefficiencies.

Another vital consideration is the flow capacity of the electric valve. This determines how effectively the valve can control the flow of the medium, be it liquid or gas. Choosing a valve with the appropriate flow characteristics for your specific application will ensure optimal performance. Additionally, factors such as pressure rating and the medium's temperature range play a major role in the longevity and reliability of the valve. Evaluating these elements against industry standards will help ensure that the selected electric valve is not only effective but also robust enough to withstand the demands of your operational environment.

Troubleshooting Common Electric Valve Failures in Industrial Settings

In industrial settings, electric valves are crucial for controlling fluid flow and maintaining system efficiency. However, they can encounter several common failures that disrupt operations. One prevalent issue is power supply failure, which can cause the valves to remain in a fixed position, impeding the process flow. Regularly checking the electrical connections and ensuring the power supply is stable can mitigate this problem. Additionally, implementing a backup power system can provide additional assurance against sudden outages.

Another frequent challenge is actuator malfunction. Electric valve actuators can wear out over time due to environmental factors, such as dust and temperature fluctuations. To troubleshoot this, operators should conduct periodic maintenance checks to identify any signs of wear or damage. Cleaning the actuator and replacing worn components can significantly extend its lifespan. Furthermore, investing in high-quality actuators designed for harsh industrial conditions can reduce the frequency of these failures, ensuring that operations remain uninterrupted and efficient.

Best Practices for Maintenance and Care of Electric Valves

Electric valves are crucial components in many industrial applications, and proper maintenance is essential to ensure their longevity and efficient operation. Regular inspection is a key practice that helps identify any signs of wear or malfunction early on. Operators should check for leaks, unusual noises, and responsive movement during routine maintenance checks. Cleaning the valve surfaces and ensuring that any accumulated dirt, grime, or debris is removed can prevent operational issues and extend the lifespan of the valves.

In addition to inspections, implementing a regular lubrication schedule is vital. Lubrication minimizes friction between moving parts, reducing wear and tear while improving the valve's responsiveness. It's important to use the right type of lubricant as specified by the manufacturer to avoid damaging the electronic components. Furthermore, operators should also keep an eye on the electrical connections, ensuring that they are tight and free from corrosion. Staying proactive with maintenance can significantly reduce downtime and repair costs, maintaining the efficiency of industrial operations.

Ultimate Guide to Choosing the Right Electric Valves for Your Industrial Needs

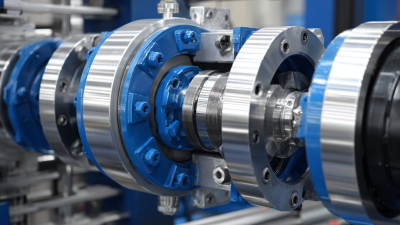

This bar chart illustrates the most common types of electric valves used in various industrial applications and their respective performance ratings. Understanding these metrics can help in selecting the right electric valve for your operational needs.

Related Posts

-

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries

-

Unlocking Performance with Best Stainless Steel Valves Comprehensive Technical Parameters and How to Choose the Right Fit

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China