Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

In the evolving landscape of industrial fluid control systems, "high performance butterfly valves" have emerged as a pivotal component in various applications due to their efficiency and versatility. According to a report by MarketsandMarkets, the butterfly valve market is projected to reach USD 8.9 billion by 2024, growing at a CAGR of 5.5%. This growth is driven by the increasing demand for efficient flow control in sectors such as oil and gas, water management, and HVAC systems. As industries seek solutions that enhance operational efficiency and reduce downtime, the importance of selecting the right type of butterfly valve becomes clear. This comprehensive tutorial delves into the world of high performance butterfly valves, exploring alternatives and providing industry insights essential for optimizing performance and ensuring reliability in demanding environments.

Understanding High Performance Butterfly Valve Types and Their Applications

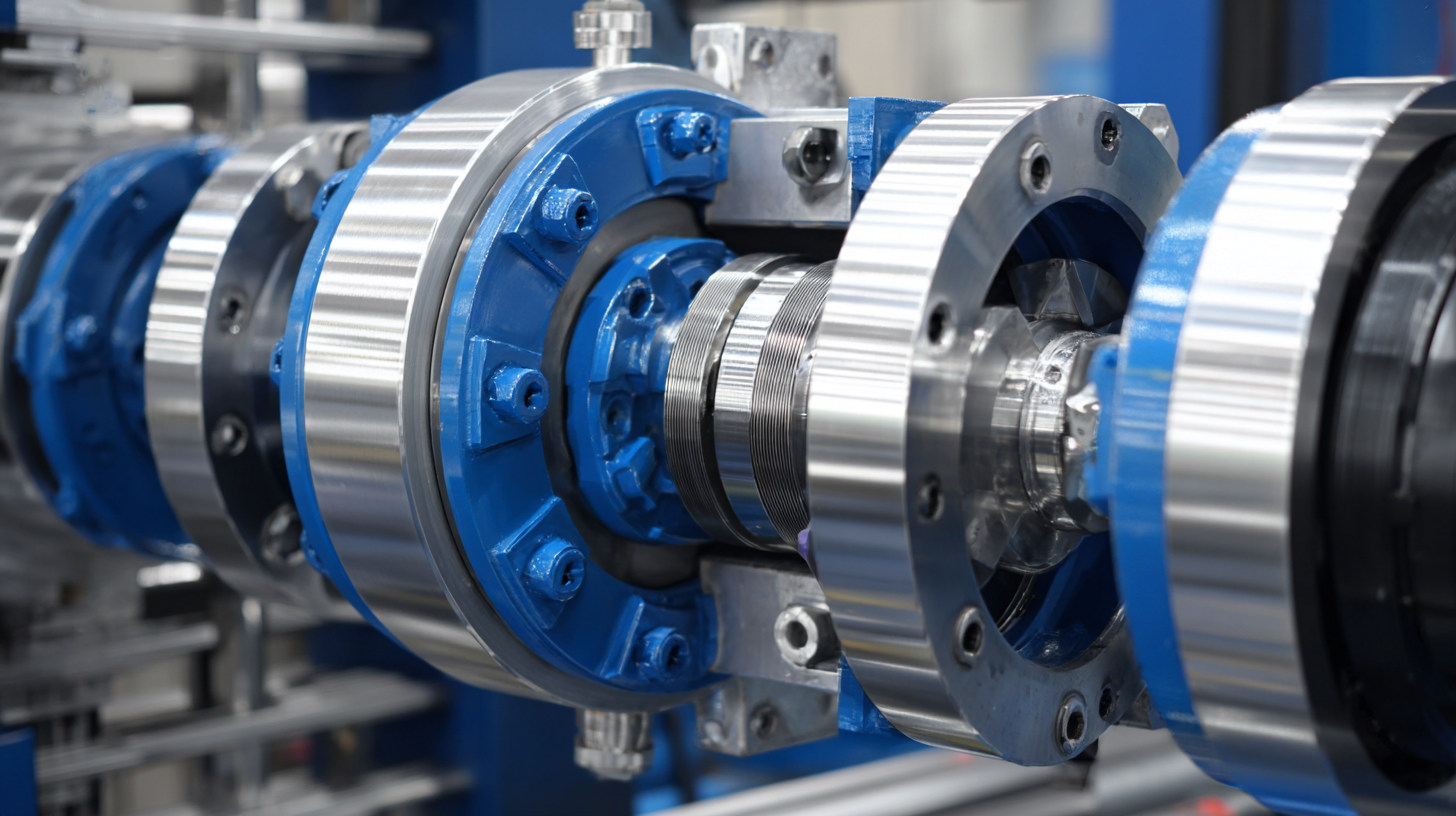

High performance butterfly valves are crucial components in various industrial applications, offering an efficient solution for flow regulation. Understanding the different types of these valves is essential for engineers and decision-makers in sectors such as oil and gas, water treatment, and chemical processing. According to a recent report by MarketsandMarkets, the global butterfly valve market is expected to reach $4.15 billion by 2025, growing at a CAGR of 4.9% from 2020. This growth underscores the importance of selecting the right type of valve for specific applications.

There are several high performance butterfly valve types, including resilient-seated, high-performance, and triple-offset designs. Each type is tailored for distinct operational needs; for example, triple-offset butterfly valves are ideal for hazardous fluids and high-pressure environments due to their superior sealing capability. A report from Research and Markets highlights that the demand for high-performance butterfly valves in the oil and gas sector alone is projected to expand significantly, driven by the increasing emphasis on safety and efficiency. By understanding these types and their applications, industries can better enhance operational performance and achieve cost savings effectively.

Mastering High Performance Butterfly Valves: A Comprehensive Tutorial with Industry Insights

| Type | Material | Size Range (inches) | Pressure Rating (PSI) | Temperature Range (°F) | Common Applications |

|---|---|---|---|---|---|

| Resilient Seated Butterfly Valve | Ductile Iron | 2 - 48 | 150 | -20 to 200 | Water Supply, Wastewater Treatment |

| High Performance Butterfly Valve | Stainless Steel | 2 - 60 | 300 | -40 to 300 | Chemical Processing, Oil & Gas |

| Triple Offset Butterfly Valve | Carbon Steel | 3 - 72 | 600 | -50 to 400 | Power Generation, Marine Applications |

| Lug Butterfly Valve | PVC | 2 - 12 | 150 | 0 to 140 | Irrigation, HVAC Systems |

Common Challenges Faced with Butterfly Valve Performance and Reliability

Butterfly valves are widely recognized for their space-saving design and efficiency in regulating flow. However, performance and reliability issues remain prevalent in the industry. According to a report by the *Valve Manufacturers Association*, nearly 25% of butterfly valves experience issues related to sealing effectiveness and flow control precision. This inconsistency not only leads to increased operational costs but can also compromise system integrity, particularly in critical applications such as chemical processing and water treatment.

One of the common challenges faced by engineers is the wear and tear of the valve seats, which can significantly impact sealing capabilities. A study published in the *Journal of Fluid Dynamics* highlights that improper installation and maintenance account for over 30% of valve failures. Moreover, the choice of material plays a crucial role; for instance, valves constructed with rubber seats tend to deteriorate faster in abrasive environments compared to those made from metal or composite materials. Implementing regular maintenance schedules and proper selection of materials tailored to specific operational conditions can substantially enhance the reliability and longevity of butterfly valves.

Mastering High Performance Butterfly Valves: Common Challenges Faced with Performance and Reliability

This bar chart represents the common challenges faced in the performance and reliability of butterfly valves. The challenges include leakage rates, pressure drop, torque requirements, and operating temperature ranges, measured across various applications in the industry.

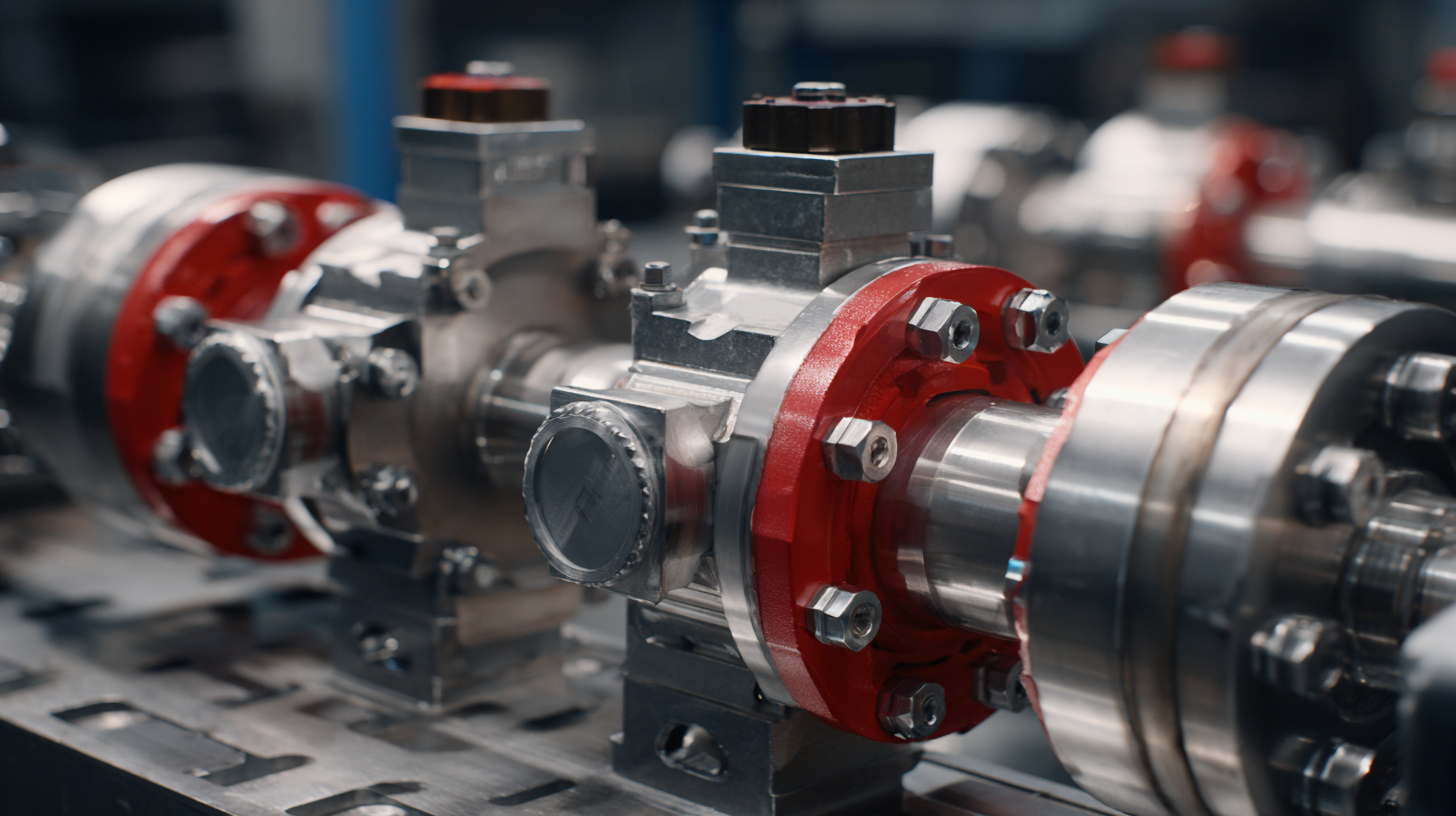

Key Factors Affecting Butterfly Valve Selection and Installation

When selecting and installing butterfly valves, several key factors significantly influence performance and reliability. Firstly, the size and pressure rating of the valve must align with the system's requirements. According to a report by the Flow Control Magazine, improper sizing can lead to flow inefficiencies of up to 35%, potentially causing operational disruptions. This emphasizes the importance of meticulous calculations during the selection process to ensure optimal flow characteristics.

Another crucial factor is the material choice for the valve. The fluid being handled plays a pivotal role in determining material compatibility. A study published by the Valve Manufacturers Association indicates that using the wrong material can reduce the valve's lifespan by as much as 50%. It is essential to consider environmental factors such as temperature and corrosiveness to select materials that can withstand the operational demands, ensuring durability and reducing maintenance costs.

Lastly, installation practices are vital in achieving high performance from butterfly valves. Proper alignment and support during installation can prevent issues such as misalignment and excessive wear. A report from the International Society of Automation highlights that proper installation techniques can enhance valve performance by up to 20%. Therefore, following industry best practices during both selection and installation is essential for maximizing the performance of butterfly valves.

Maintenance Best Practices for Optimizing Butterfly Valve Lifespan

To ensure the longevity and optimal performance of butterfly valves, regular maintenance is essential. One best practice involves establishing a routine inspection schedule to check for any signs of wear or damage. Look for issues such as seat wear, corrosion, or misalignment. Early detection of these problems can prevent more serious failures down the line, saving both time and money.

To ensure the longevity and optimal performance of butterfly valves, regular maintenance is essential. One best practice involves establishing a routine inspection schedule to check for any signs of wear or damage. Look for issues such as seat wear, corrosion, or misalignment. Early detection of these problems can prevent more serious failures down the line, saving both time and money.

Another critical aspect of maintenance is lubrication. Using the correct type of lubricant on the valve shaft can minimize friction and wear with regular use. Maintaining a clean environment around the valve is equally important; dirt and debris can cause abrasion and hinder the valve's operation. Finally, don't overlook the importance of proper installation and alignment when the valve is first commissioned, as this sets the stage for reliable long-term performance. By implementing these best practices, operators can significantly extend the lifespan of butterfly valves while ensuring they perform at peak efficiency.

Industry Insights: Innovations and Trends in Butterfly Valve Technology

The butterfly valve industry has seen remarkable innovations in recent years, driven by the increasing demand for efficiency and sustainability. One of the most significant trends is the integration of smart technology into valve design. Smart butterfly valves equipped with IoT capabilities allow for real-time monitoring and predictive maintenance, reducing downtime and optimizing operation. This advancement not only enhances performance but also contributes to the overall efficiency of industrial processes, making them more responsive to changing demands.

Another noteworthy trend is the development of new materials and coatings that improve the durability and performance of butterfly valves in challenging environments. Advances in polymer and composite materials have led to valves that resist corrosion and wear, extending their lifespan and reducing maintenance costs. Additionally, manufacturers are now focusing on eco-friendly materials to meet increasing regulatory requirements and promote sustainability in industrial applications. These innovations highlight the industry's commitment to enhancing both performance and environmental responsibility, positioning butterfly valves as a critical component in modern fluid control systems.