How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries

In today's competitive industrial landscape, optimizing process efficiency is paramount, and the selection of the right components plays a critical role in achieving this goal. One such component is the actuated butterfly valve, which has become increasingly essential in streamlining operations across various sectors. According to a recent market report by Valuates Reports, the global butterfly valve market is projected to grow at a CAGR of 4.3% from 2021 to 2028, driven by rising demand for efficient flow control solutions in oil and gas, water treatment, and HVAC applications.

As industries strive to enhance productivity and reduce energy consumption, understanding the nuances of how to select the best actuated butterfly valve is crucial for ensuring optimal performance and cost-effectiveness. This blog will explore the key factors to consider when making this selection, emphasizing the impact of high-quality valves on overall operational efficiency.

Understanding the Role of Actuated Butterfly Valves in Industrial Processes

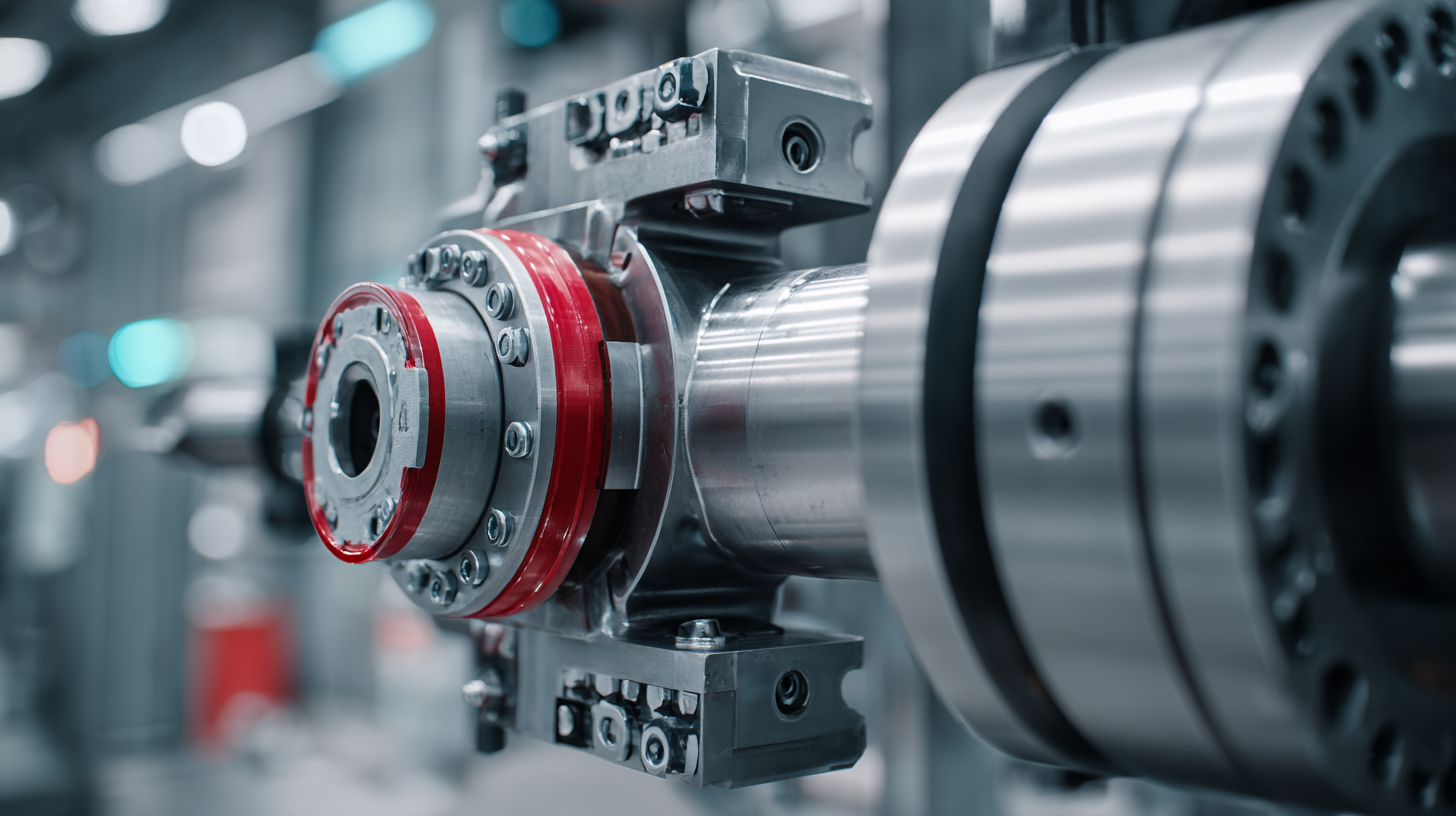

In various industrial processes, actuated butterfly valves play a pivotal role in controlling the flow of liquids and gases. These valves, characterized by their quarter-turn operation and compact design, provide significant benefits in terms of space and weight. Their ability to quickly and efficiently regulate flow makes them a preferred choice in applications ranging from water treatment to chemical processing. By integrating automation with butterfly valves, industries can enhance operational efficiency, reduce manual labor, and minimize the risk of leaks.

Moreover, the versatility of actuated butterfly valves allows them to adapt to different media and pressure conditions, making them suitable for diverse industrial applications. Advanced actuator technologies, such as electric and pneumatic actuators, provide precise control over the valve position, which is crucial for maintaining process stability. Understanding the specific requirements of your application—such as temperature, pressure, and flow rates—is essential when selecting the right valve. This ensures optimal performance and longevity, ultimately contributing to the overall efficiency of industrial processes across global industries.

Key Features to Look for When Selecting Actuated Butterfly Valves

When selecting the best actuated butterfly valve for optimal process efficiency in global industries, several key features must be prioritized.

Firstly, the materials used in the valve construction are critical. Valves made from durable, corrosion-resistant materials can enhance longevity and resilience in various industrial environments.

This is especially important when the valve is exposed to harsh chemicals or extreme temperatures.

Another essential feature is the actuator mechanism. Choosing between electric, pneumatic, or hydraulic actuators can significantly influence the valve’s performance.

Electric actuators offer precision control and easy integration with automated systems, while pneumatic actuators are known for their rapid response times.

Additionally, the size and type of the valve should correspond with the specific application, ensuring that it can handle the required flow rates and pressure levels efficiently.

By focusing on these features, industries can optimize their processes while ensuring reliability and performance in their systems.

Impact of Emerging Technologies on Butterfly Valve Performance

Emerging technologies are significantly transforming the performance and efficiency of actuated butterfly valves across various industries. Advanced materials such as composites and alloys are enhancing the durability and corrosion resistance of these valves. According to a report by Technavio, the global butterfly valve market is projected to grow at a CAGR of 5% from 2021 to 2025, driven by the increasing demand for optimized fluid control solutions in sectors like oil and gas, water treatment, and chemical processing.

Moreover, the integration of smart technology for real-time monitoring is revolutionizing how these valves operate. IoT-enabled devices facilitate predictive maintenance, which can reduce downtime by up to 30%, as noted in a report by Gartner. This shift means that industries can not only improve their operational efficiencies but also minimize waste and energy consumption, aligning with global sustainability goals.

As companies continue to invest in automation and digitalization, the impact on butterfly valve performance will become increasingly pronounced, paving the way for innovative designs and functionalities that cater to the evolving demands of the marketplace.

Best Practices for Integrating Actuated Butterfly Valves in Global Operations

When integrating actuated butterfly valves into global operations, it is essential to consider several best practices that enhance efficiency and reliability. First, selecting the right materials is crucial. Depending on the application, materials such as stainless steel, PVC, or exotic alloys can resist corrosion and pressure variations. This selection ensures that the valves operate optimally under different environmental conditions, reducing maintenance costs and downtime.

Another important aspect is the proper sizing and selection of actuators. Actuated butterfly valves must be sized correctly to match the flow requirements of the system. Over-sized or under-sized valves can lead to inefficiencies and operational issues. Additionally, choosing the appropriate actuator — whether electric, pneumatic, or hydraulic — is vital for achieving precise control and faster response times. Implementing a performance monitoring system allows operators to track the efficiency and reliability of the valves, facilitating timely adjustments and preventive maintenance.

Training personnel on valve operation and maintenance enhances operational efficiency significantly. Ensuring that staff understands the functionality and application of the valves can prevent mishaps and allow for prompt troubleshooting of any issues. Regular training sessions and updated operational manuals will cultivate a knowledgeable workforce adept at managing the complexities of actuated butterfly valves in diverse global environments.

Future Trends in Butterfly Valve Technology for Enhanced Efficiency

The future of butterfly valve technology is being shaped by innovative advancements aimed at enhancing efficiency in global industries. According to a recent report by MarketsandMarkets, the global butterfly valve market is projected to reach USD 7.12 billion by 2026, growing at a CAGR of 4.8% from 2021 to 2026. This growth is driven by the increasing demand for automation in process industries, where precise flow control is crucial.

One key trend is the integration of smart technologies into butterfly valves, allowing for real-time monitoring and predictive maintenance. By employing IoT-enabled devices, industries can optimize valve performance, reduce downtime, and minimize operational costs. Additionally, new materials and manufacturing techniques are enhancing the durability and efficiency of these valves. For instance, advancements in composite materials provide better resistance to corrosion, which is essential in harsh industrial environments. As industries increasingly prioritize sustainability, these innovations not only improve efficiency but also contribute to lower energy consumption and reduced emissions, aligning with global efforts towards greener practices.