Top 10 Globe Valve Types You Need to Know for Your Projects

When it comes to fluid control in various engineering projects, understanding the different types of valves is essential. Among these, the globe valve stands out as a crucial component known for its ability to provide reliable throttling and isolation. Designed with a spherical body, globe valves allow for precise flow regulation, making them a preferred choice in applications ranging from waterworks to chemical processing.

In this article, we will explore the top 10 globe valve types that every engineer and project manager should be familiar with. Each type presents unique characteristics and advantages that cater to specific application needs, ranging from high-pressure environments to situations requiring quick shut-off. By delving into these various globe valve types, you will gain valuable insights that will enhance your understanding and improve your decision-making in valve selection for your projects. Emphasizing the versatility and functionality of the globe valve, this discussion aims to equip you with the knowledge needed to choose the right valve type for your unique needs.

Understanding the Basics of Globe Valves

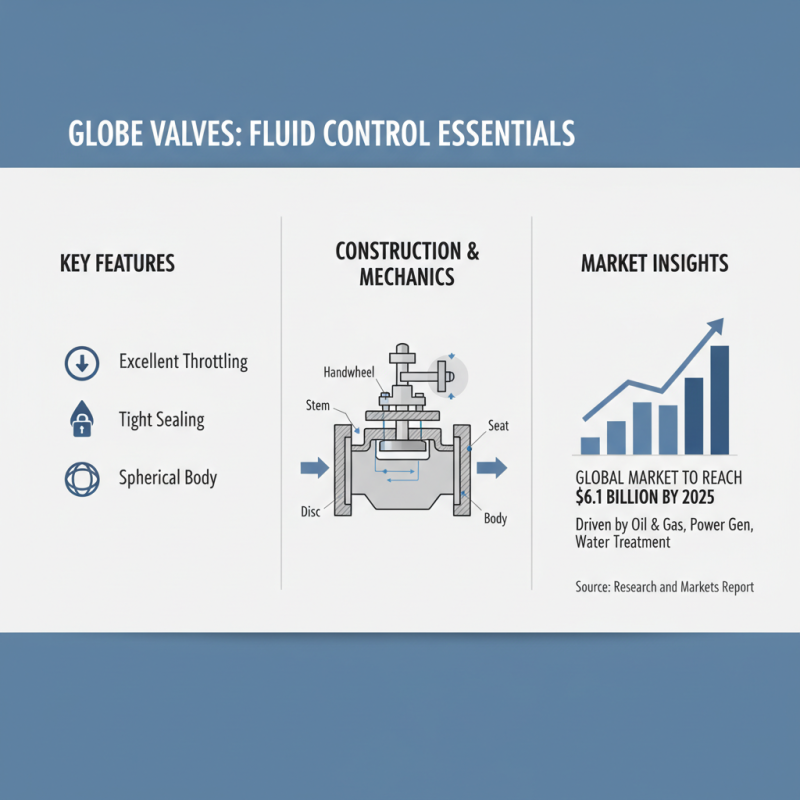

Globe valves are a crucial component in various fluid control applications, known for their excellent throttling capabilities and tight sealing features. They are characterized by a spherical body shape that allows for significant flow control. According to a recent market analysis report from Research and Markets, the global globe valve market is projected to reach $6.1 billion by 2025, driven by increasing demand in oil and gas, power generation, and water treatment industries. Understanding the basics of globe valves, including their construction and operational mechanics, is essential for engineers and project managers involved in system design and maintenance.

The design of a globe valve comprises a movable disk and a stationary ring seat, which helps to regulate flow. This structure allows for smooth and efficient operation even under high-pressure conditions. The American Society of Mechanical Engineers (ASME) has outlined standards for globe valves, emphasizing their ability to handle diverse temperature and pressure ranges. Notably, globe valves are often preferred in high-pressure applications, as they can withstand pressure drops while maintaining precise flow control. Furthermore, the valve's ability to completely shut off flow makes it suitable for applications where reliability is a critical factor. Understanding these fundamentals enables professionals to make informed decisions about valve selection for specific project needs.

Different Types of Globe Valves Explained

Globe valves are essential components in various industrial applications, offering precise flow control and throttling capabilities. Among the different types available, the standard globe valve features a spherical body with an internal baffle that directs fluid flow in a straight line. This design allows for excellent control, making it suitable for applications requiring frequent adjustments in flow rates. Variation in size and material can be tailored to specific environments, ensuring durability and performance.

Another notable type is the angle globe valve, which modifies the flow path by altering the valve's orientation. This design is particularly beneficial in piping systems where space limitations exist, as it provides a compact solution without compromising on flow control. Additionally, the Y-pattern globe valve is designed for high-pressure applications, offering a streamlined flow path that minimizes pressure drop. These various types of globe valves cater to different operational needs, allowing engineers to select the most suitable option based on their project's specific requirements. Understanding these differences is crucial for optimizing system performance and ensuring efficient operation.

Advantages and Disadvantages of Each Globe Valve Type

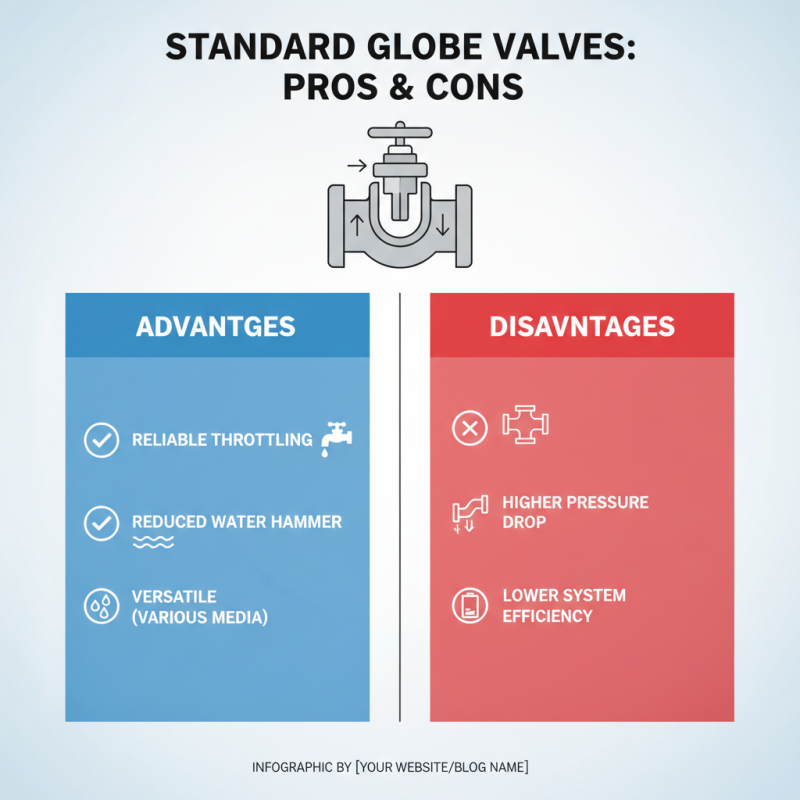

When selecting a globe valve for your project, it is essential to weigh the advantages and disadvantages of each type. For instance, standard globe valves are known for their reliable throttling capabilities and reduced water hammer effects. They are ideal for flow control and can handle various media, making them versatile. However, their design leads to a higher pressure drop compared to other valve types, which can negatively impact system efficiency.

Another popular type is the angle globe valve, which offers a more compact design and minimizes the effect of flow turbulence. This can result in better performance in confined spaces. Despite these advantages, angle globe valves may have limited applications in certain setups due to their specific flow direction requirements. On the other hand, Y-pattern globe valves provide improved flow characteristics and reduced turbulence, making them suitable for high-pressure applications. Still, their complex structure can lead to increased manufacturing costs and maintenance challenges, requiring careful consideration during the selection process.

Applications of Globe Valves in Various Industries

Globe valves play a critical role across various industries due to their superior throttling capabilities and versatility. In the oil and gas sector, for instance, these valves are essential for regulating flow and maintaining pressure in pipelines. According to a report by Global Market Insights, the global oil and gas valves market is projected to exceed $30 billion by 2026, with a significant portion attributed to globe valves due to their ability to handle high-pressure systems effectively. Their design allows for precise flow control, making them indispensable in operations such as refining and distribution.

In the water treatment industry, globe valves are frequently utilized to manage flow rates in treatment plants and distribution systems. The American Water Works Association (AWWA) notes that proper control mechanisms, such as globe valves, are vital for ensuring the efficiency of treatment processes and preventing system overloads. As environmental regulations tighten globally, the demand for reliable and efficient flow control solutions, including globe valves, is on the rise. This trend underscores the importance of understanding the various types of globe valves available for projects aimed at improving water quality and service reliability in municipal applications.

These applications highlight the necessity of integrating globe valves into projects across diverse sectors, making them a vital component in contributing to system efficiency and operational integrity.

Top 10 Globe Valve Types You Need to Know for Your Projects

| Valve Type | Application | Industries | Pressure Rating |

|---|---|---|---|

| Standard Globe Valve | Flow regulation | Oil & Gas | ANSI Class 150 to 900 |

| Angular Globe Valve | Flow control in tight spaces | Chemical Processing | ANSI Class 150 to 600 |

| Pressure Relief Globe Valve | Safety applications | Petrochemical | ANSI Class 300 |

| Expansion Globe Valve | Temperature control | Power Generation | ANSI Class 150 to 600 |

| Cryogenic Globe Valve | Liquid gas control | LNG Facilities | ANSI Class 150 to 300 |

| Electric Globe Valve | Automated flow control | Water Treatment | ANSI Class 150 to 600 |

| Hydraulic Globe Valve | Fluid handling | Manufacturing | ANSI Class 150 to 900 |

| High-Performance Globe Valve | High pressure and temperature | Power Generation | ANSI Class 600 to 1500 |

| Stainless Steel Globe Valve | Corrosive fluid handling | Pharmaceutical | ANSI Class 150 to 600 |

| Forged Steel Globe Valve | Durability in extreme conditions | Oil & Gas | ANSI Class 600 to 2500 |

Maintenance Tips for Ensuring Globe Valve Performance

Proper maintenance is crucial for ensuring the optimal performance of globe valves, which are essential components in a variety of industrial applications. Regular inspections play a vital role in identifying any potential issues before they escalate. Begin with routine visual checks for leaks, corrosion, and the overall condition of the valve body and seals. Move on to monitoring the actuator's performance, ensuring that it operates smoothly without excessive force or delay. Additionally, maintaining a precise flow rate can help avoid excessive wear and tear on the valve, prolonging its lifespan.

Lubrication is another key aspect of globe valve maintenance. Ensure that the threads and moving parts are properly lubricated to facilitate smooth operation and prevent galling. It is also important to flush the valve periodically to remove any debris or sediment that may impede its functionality. Finally, pay close attention to the valve's closing mechanism. Regularly checking the seating surface for damage or wear will help maintain a tight seal, which is critical for preventing leaks and ensuring efficient operation. By following these maintenance tips, you can help secure the integrity and reliability of your globe valves in any project.

Top 10 Globe Valve Types Performance Comparison

This chart illustrates the performance efficiency of the top 10 globe valve types based on data gathered from various applications. Understanding these performance metrics is essential for selecting the right valve for your projects.

Related Posts

-

Understanding the Future of Automated Valves in Modern Industry Technology

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

How to Optimize Your System Efficiency with Automated Valves

-

How to Select the Best Actuated Butterfly Valve for Optimal Process Efficiency in Global Industries

-

Exploring the Future of Actuated Valves: Innovations Shaping the Global Market Growth to $10 Billion by 2028

-

Emerging Trends in Butterfly Valves Industry Exhibited at China Import and Export Fair 2025