10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability

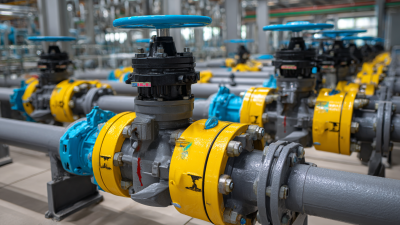

The increasing demand for efficient flow control solutions in various industries has brought the triple offset butterfly valve to the forefront of modern engineering. According to a report by ResearchAndMarkets, the global butterfly valve market is projected to reach $6.2 billion by 2026, driven by the growing need for reliable and durable valve technologies. Triple offset butterfly valves, known for their unique design that minimizes wear and tear while ensuring tight sealing, play a crucial role in enhancing operational efficiency in sectors like oil and gas, water treatment, and power generation. Their ability to withstand high pressure and temperature fluctuations makes them especially suitable for demanding applications. This article delves into the ten best triple offset butterfly valves currently available, highlighting their features, advantages, and the impact they have on system performance and longevity.

The increasing demand for efficient flow control solutions in various industries has brought the triple offset butterfly valve to the forefront of modern engineering. According to a report by ResearchAndMarkets, the global butterfly valve market is projected to reach $6.2 billion by 2026, driven by the growing need for reliable and durable valve technologies.

Top Features to Look for in Triple Offset Butterfly Valves

When selecting a triple offset butterfly valve, there are several key features to consider that significantly enhance both efficiency and durability. First and foremost, the design of the valve seat is crucial. A reliable triple offset valve typically features a metal-to-metal seating arrangement, which ensures a tight seal and allows for operation under high pressure and temperature conditions. This is especially important in industrial applications where failure to maintain integrity can lead to costly downtime and safety hazards.

Another important aspect is the valve body materials. Opting for high-quality alloys or corrosion-resistant materials can greatly extend the lifespan of the valve while enhancing performance in aggressive environments. Additionally, look for valves that incorporate an adjustable packing system, which not only minimizes leakage but also allows for easy maintenance. The choice of actuator type—manual, pneumatic, or electric—also plays a vital role in improving the operational efficiency of the system. By prioritizing these features, you can ensure that your triple offset butterfly valve performs reliably over time, contributing to overall system effectiveness.

Comparative Analysis of the Leading Triple Offset Butterfly Valves

When it comes to selecting the best triple offset butterfly valves, a comparative analysis reveals significant differences in features, efficiency, and durability among various models. Each manufacturer offers unique benefits, but it's essential to focus on aspects such as body material, sealing technology, and operating pressure ratings. These factors can greatly influence the valve's performance in demanding conditions, making it crucial to choose a valve that not only meets the requirements of the application but also promises longevity and minimal maintenance.

**Tips**: When evaluating triple offset butterfly valves, prioritize those with advanced sealing mechanisms, as they can offer improved leak prevention and operational reliability. Additionally, consider the valve's compatibility with the fluids you intend to manage, as incompatible materials could lead to premature wear or corrosion, ultimately affecting performance. Always review the manufacturer's warranty and support services, as reputable brands often provide enhanced assistance in case issues arise, ensuring your investment is protected.

The comparative analysis should also encompass the cost-effectiveness of various models. While initial prices may vary, the total cost of ownership—factoring in maintenance, replacement parts, and energy efficiency—can significantly impact the overall value of the valve over time. Opting for a more durable valve may seem like a higher upfront investment, yet it can lead to substantial savings in the long run by reducing downtime and maintenance costs.

The Benefits of Using Triple Offset Butterfly Valves in Industrial Applications

Triple offset butterfly valves are increasingly recognized for their exceptional efficiency and durability in various industrial applications. These valves feature a unique design that minimizes friction and wear during operation, allowing for smoother and more reliable flow control. The precise alignment of the sealing surfaces reduces leakage, making them suitable for applications requiring strict fluid containment. Additionally, their robust construction ensures longevity, reducing the need for frequent repairs or replacements, which can enhance overall operational efficiency.

Tips for selecting the right triple offset butterfly valve include assessing the specific fluid characteristics, such as temperature and pressure, as well as considering the installation environment. Ensuring that the valve materials are compatible with the fluid will prevent premature degradation. It's also beneficial to consult with manufacturers to understand the unique features of their designs, as this can lead to improved performance tailored to individual needs.

Another critical tip is to prioritize valves with comprehensive testing certifications. Valves that have undergone rigorous quality assessments tend to provide better performance and reliability. Moreover, regular maintenance checks can prolong the lifespan of these valves, ensuring that they continue to operate efficiently over time in demanding industrial settings.

Maintenance Tips for Prolonging the Life of Butterfly Valves

When it comes to maximizing the longevity and performance of triple offset butterfly valves, proper maintenance is crucial. Regular inspection and cleaning can prevent the accumulation of debris and corrosive substances that may lead to valve malfunction. According to a report by the International Journal of Industrial Valve Engineering, nearly 30% of valve failures are attributed to inadequate maintenance practices. Implementing a routine maintenance schedule that includes visual inspections and periodic disassembly can significantly mitigate these risks.

Additionally, lubrication plays a vital role in the operational efficiency of butterfly valves. Specialty lubricants, specifically formulated for high-temperature and high-pressure environments, can enhance the seal integrity and reduce friction. The Valve Manufacturers Association states that using the right lubricant can extend service life by up to 50%. Operators should also be mindful of the environmental conditions where valves are installed, as extreme temperatures and pressure fluctuations can affect their performance. Keeping track of these variables ensures that the valves are functioning optimally and reduces the likelihood of premature wear or failure.

10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability

This chart displays the efficiency ratings of the top 10 triple offset butterfly valves, showcasing their performance levels. A higher rating indicates better efficiency and durability.

Innovative Technologies in the Latest Triple Offset Butterfly Valve Models

The latest advancements in triple offset butterfly valve technology highlight a significant shift towards enhanced efficiency and durability, making these products essential for critical industries. One of the standout innovations is the introduction of high-performance valve series designed to handle extreme conditions, such as ultra-high pressure applications. According to a recent industry report, the demand for high-pressure valves is anticipated to grow at a compound annual growth rate (CAGR) of 5.9% over the next five years, emphasizing the importance of reliable solutions in sectors like oil and gas, power generation, and chemical processing.

Moreover, the adoption of innovative materials and design enhancements in recent models contributes to longer service life and lower maintenance costs. Advanced sealing technologies and streamlined flow paths are just a few examples of how modern triple offset butterfly valves are engineered to minimize leakage and optimize performance. A survey by a leading engineering firm indicates that manufacturers are increasingly prioritizing these features, with over 70% of respondents emphasizing the need for durability and efficiency in their valve choices. As the industry evolves, staying ahead with cutting-edge valve technology will be crucial for maintaining competitive advantages and meeting operational demands.

10 Best Triple Offset Butterfly Valves for Enhanced Efficiency and Durability

| Model | Diameter (inches) | Pressure Rating (PSI) | Material | Temperature Range (°F) | Features |

|---|---|---|---|---|---|

| Model A | 2 | 150 | Stainless Steel | -20 to 300 | Fire-safe Design |

| Model B | 4 | 200 | Carbon Steel | -10 to 250 | Low Torque Requirements |

| Model C | 6 | 300 | Alloy Steel | -40 to 400 | Anti-Static |

| Model D | 8 | 150 | Ductile Iron | 0 to 300 | Flexible Seat Design |

| Model E | 10 | 250 | Bronze | -20 to 350 | Low Resistance to Flow |

Related Posts

-

Quality that Conquers Global Markets the Rise of Best Triple Offset Butterfly Valves from China

-

Understanding the Varieties of Cast Iron Butterfly Valves in Industrial Applications

-

How to Optimize Your Pipeline Efficiency with Butterfly Valves in the UK: Key Insights and Data

-

5 Reasons Why Actuated Butterfly Valves Are the Best Choice for Efficient Flow Control

-

Innovative Examples of Stainless Steel Ball Valves Enhancing Efficiency in Industrial Applications

-

How to Optimize Your System Efficiency with Automated Valves